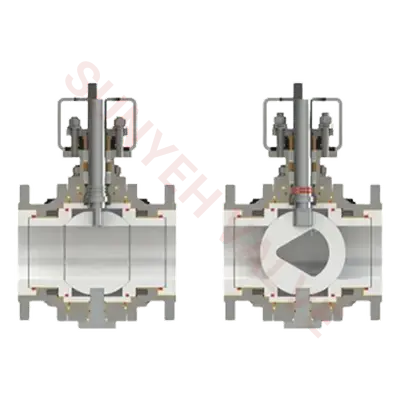

Introduction of Zirconia Ceramic Lined Ball Valves

The lining ceramic of the zirconia ceramic lined ball valves is made of 99.9% high purity zirconia ceramic. Its chemical properties are stable, with high hardness, and can withstand the corrosion of most acid and alkali media. Additionally, it has excellent wear and erosion resistance.

Characteristics of Zirconia Ceramic Lined Ball Valves

Wear Resistance

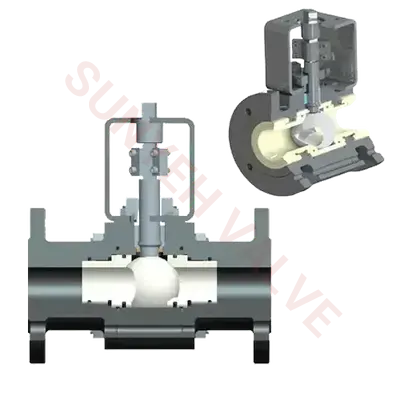

The zirconia ceramic lined ball valves adopt a fully lined zirconia ceramic structure with a hardness of HRC87~90, second only to diamond. Due to its high hardness, it can cope with most wear conditions and is suitable for media such as particles, powder, and slurry.

Long Service Life

The excellent wear resistance of ceramics makes the zirconia ceramic lined ball valves durable and extremely reliable. Its service life is 2-4 times that of titanium alloy valves and 4-6 times that of 304 stainless steel valves.

Corrosion Resistance

The lining structure ceramic uses zirconia with a purity of 99.9% as the raw material, which can resist the corrosion of most acid and alkali media and has stable chemical properties.

High Sealing Level

The ceramic valve seat and valve ball of the lining use advanced manufacturing technology, with high precision and good quality, providing excellent sealing performance. This overcomes the shortcomings of metal hard-sealed ball valves such as easy leakage, high torque, and poor wear resistance of the sealing surface.

Customization

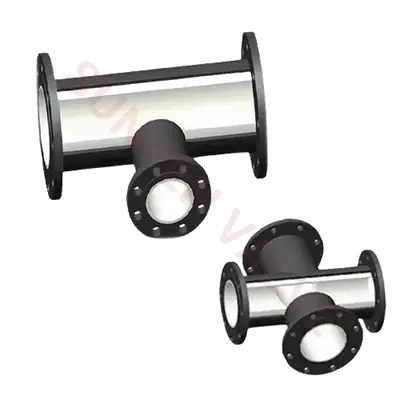

The valve length, installation method, and actuator connection size can be customized according to user requirements, maximizing the fulfillment of users' on-site usage needs and facilitating on-site installation by users.

Easy Maintenance

The valve adopts a three-piece structure, which can be dismantled. The ceramic components are easy to replace, reducing subsequent maintenance costs.

Advantages of Zirconia Ceramic Lined Ball Valves

The zirconia ceramic lined ball valves use toughened zirconia, which has extremely high chemical stability and hardness. It possesses excellent wear resistance, corrosion resistance, erosion resistance, and also good thermal insulation. Its low thermal expansion coefficient, high hardness, and high electrical and thermal insulation properties make it superior to other materials in terms of performance.

The zirconia ceramic lined ball valves are also widely used in harsh conditions where it is difficult to use metal or other materials, such as chemical equipment, waste incineration equipment, and flue gas desulfurization equipment. It covers industrial fields such as power generation, petroleum, chemical engineering, metallurgy, mining, and sewage treatment.

English

English