The steel industry is one of the foundational sectors of modern society, and in its vast industrial chain, processes such as sintering, ironmaking, and steelmaking are indispensable. These stages require handling high-temperature reactions and materials transport, and they impose extreme demands on equipment materials due to high temperatures, high pressures, and strong corrosive conditions. This is especially true in processes requiring precise control over material flow, such as PCI (Pulverized Coal Injection) and EAF (Electric Arc Furnace), where equipment must meet very high standards for sealing, wear resistance, and high-temperature tolerance.

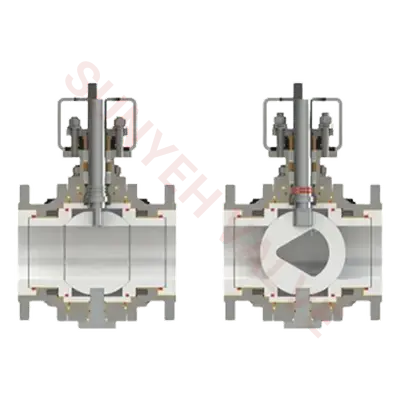

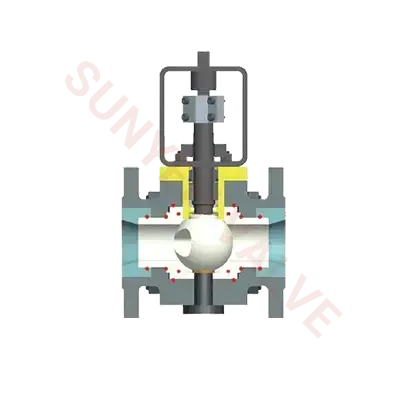

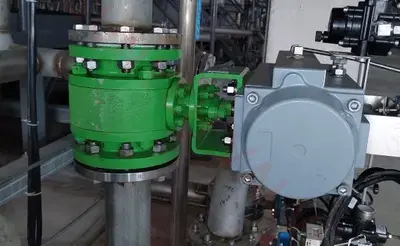

In these applications, Sun Yeh ceramic-lined control valves stand out due to their exceptional performance. These valves are lined with high-performance ceramic material that is not only high-temperature resistant and wear-resistant but also highly corrosion-resistant. For instance, in the desulfurization systems of sinter machines, the SDA (Spray Dry Absorption) process requires valves to operate at temperatures of 70-90°C, withstand pressures of 1.0 MPa, and handle flue gases containing 15%–40% hydrated lime slurry. These conditions are highly demanding on valve materials as hydrated lime slurry is corrosive, and the dust in the flue gases can cause severe wear. Sun Yeh ceramic-lined control valves are up to this challenge; their highly wear-resistant and corrosion-resistant linings ensure that the valves maintain good sealing and durability even under harsh conditions.

Moreover, in high-temperature operations such as at the 700°C outlet of high-temperature fans, Sun Yeh ceramic-lined control valves also demonstrate excellent performance. Their lining materials maintain stable physical and chemical properties at high temperatures, not deforming or degrading even after prolonged exposure to high heat. The high hardness of the ceramic material also ensures that the valves remain undamaged in the presence of highly abrasive gases.

Beyond their excellent performance in high-temperature and highly corrosive conditions, Sun Yeh ceramic-lined control valves also offer significant advantages in terms of service life and maintenance costs. Due to their wear-resistant and corrosion-resistant properties, these valves seldom require repairs or replacements, thereby significantly saving operational costs. Additionally, their use of advanced sealing technology and materials further enhances production efficiency and environmental standards.

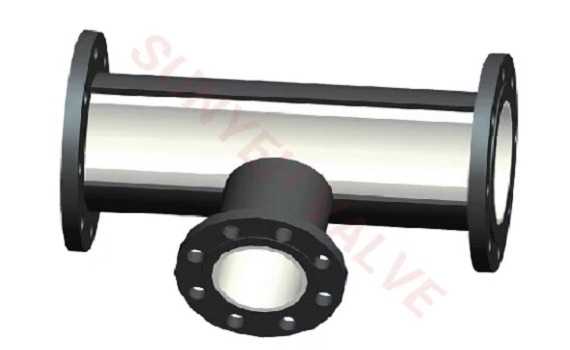

Beyond their critical role in processes like PCI and EAF, Sun Yeh ceramic-lined control valves also play a positive role in other important scenarios. For example, in the desulfurization of iron ore, these valves precisely control the amount of desulfurizing agent added, effectively improving desulfurization efficiency. During the refining process of iron ore, the valves adjust the flow of gases and fuel to control temperature and pressure, ensuring the quality and performance of the iron ore.

In summary, Sun Yeh ceramic-lined control valves, with their outstanding performance and reliable quality, have gained widespread recognition and praise in the steel industry. They not only solve the challenge of choosing valve materials under high-temperature and highly corrosive conditions but also enhance production efficiency, reduce operational costs, and strengthen environmental awareness, providing robust support for the production of steel enterprises and promoting technological progress and sustainable development in the steel industry.

English

English