Ceramic-lined pipe fittings are widely used in industries such as mining, chemical engineering, and metallurgy. Thanks to their excellent wear resistance, corrosion resistance, and high-temperature tolerance, they have become crucial components in these sectors. The selection of various fittings is particularly important to ensure the proper functioning of pipe systems.

Ceramic-Lined Elbows

Among ceramic-lined pipe fittings, elbows are one of the most common accessories. They are used at the parts of the pipe system where it turns or changes the direction of fluid flow. By utilizing an inner ceramic lining, ceramic-lined elbows can effectively enhance their wear resistance, reducing damage to the pipe caused by materials such as slurry and particulates. Especially in the mining and metallurgical industries, ceramic-lined elbows can significantly extend the service life of the pipe system, reducing the frequency of replacements.

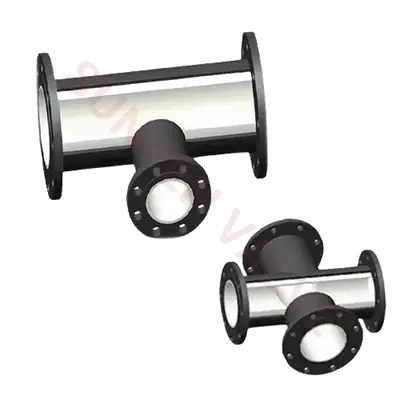

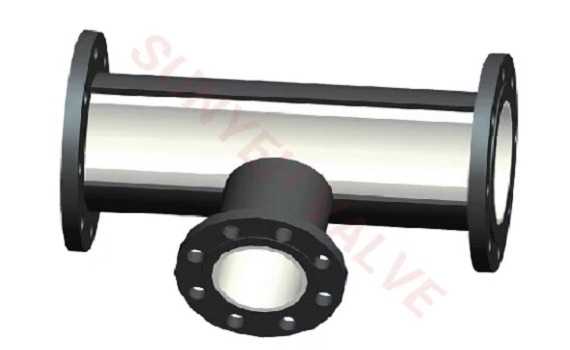

Ceramic-Lined Tees and Crosses

Ceramic-lined tees and ceramic-lined crosses are fittings used for branching or converging in pipe systems. They are typically found in scenarios requiring multi-directional material flow. Since these fittings often endure high-velocity and high-pressure fluids, ceramic-lined tees and crosses can effectively prevent wear issues caused by material flow. The ceramic lining not only improves wear resistance but also increases the corrosion resistance of these fittings, ensuring long-term stable operation.

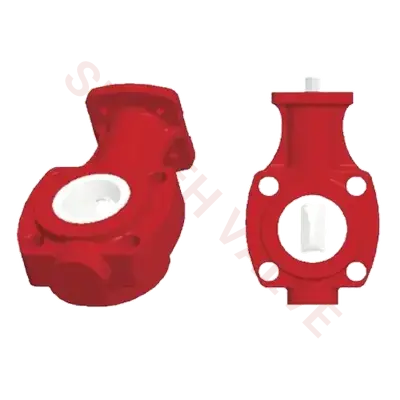

Ceramic-Lined Flanges

Ceramic-lined flanges are among the ceramic-lined pipe fittings used to connect pipes to other equipment or pipes. The corrosion and wear resistance of flanges are crucial for the stability of the entire pipe system. By utilizing the properties of ceramic materials, ceramic-lined flanges greatly improve their durability, especially in high-temperature, high-pressure, or severely chemically corrosive environments. They can effectively prevent corrosion or wear of conventional flanges during use.

eramic-Lined End Caps

Ceramic-lined end caps are generally used to seal the ends of pipes, preventing fluid leakage or influence from external environments. Ceramic-lined end caps ensure a tight seal and also protect the ends of the pipe from corrosion or other mechanical damage. Due to the high hardness and wear resistance of ceramic materials, ceramic-lined end caps can maintain stable performance under extreme conditions, extending the pipe's service life.

Ceramic-Lined Couplings

Ceramic-lined couplings are mainly used to connect two sections of a pipe, serving the purpose of docking and transition. Traditional pipe connections are prone to wear or corrosion, but ceramic-lined couplings enhance the wear resistance and corrosion resistance of the connection points through the inner ceramic lining. In certain special environments, such as slurry transportation and chemical medium transportation, ceramic-lined couplings can effectively protect the pipe junctions, preventing leaks or damage caused by wear or corrosion.

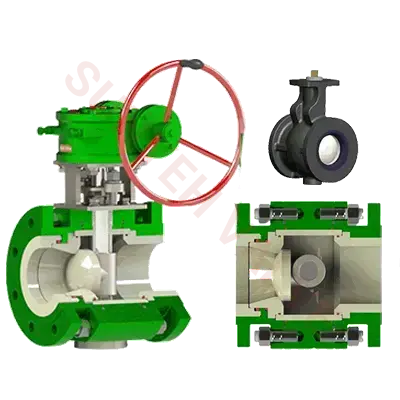

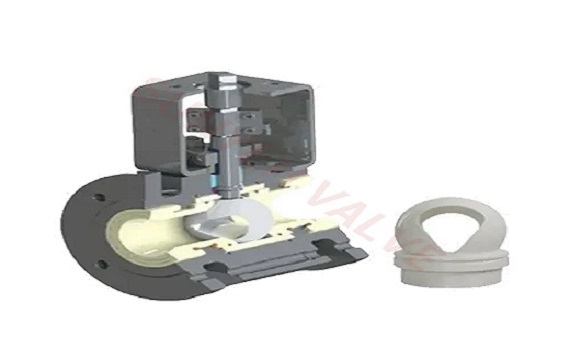

Ceramic-Lined Check Valves

Ceramic-lined check valves are key fittings used to prevent fluid backflow, widely applied in pipe systems requiring unidirectional flow. The ceramic lining of ceramic-lined check valves can effectively increase the valve's wear resistance and corrosion resistance, maintaining good sealing performance in harsh environments and preventing reverse fluid flow. Their performance is particularly outstanding in highly corrosive or highly abrasive environments.

Ceramic-lined pipe fittings come in a variety of forms, each playing an important role in different pipe systems. These fittings allow pipe systems to maintain good performance in high-wear, high-corrosion, high-pressure, and high-temperature environments. The use of these ceramic-lined pipe fittings greatly enhances the stability and service life of pipes, making them an indispensable part of modern industrial pipe systems.

English

English