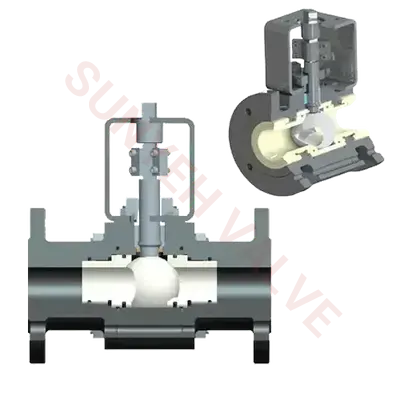

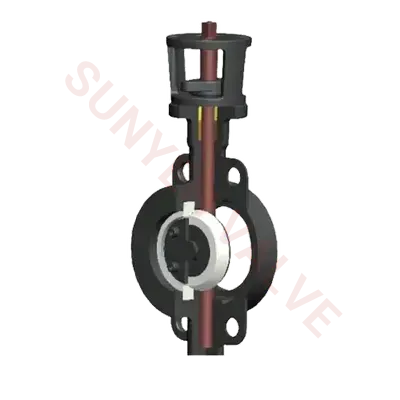

Zirconia ceramic lined ball valve not only has most of the advantages of metal ball valves but also possess exceptional features such as ultra-strong corrosion resistance, high-temperature resistance, wear resistance, and erosion resistance. They are widely used in petrochemical, metallurgy, paper-making, power plants, refining industries, and other industries for various acid, alkaline gas, liquid, high-temperature steam, and slurry transportation systems. They are ideal substitutes for titanium metal valves and Monel valves in highly corrosive environments. Sunyeh zirconia ceramic-lined ball valves have the advantages of low cost, high operational economy, and long service life (generally 2 to 4 times that of titanium valves). They are available in manual, pneumatic, pneumatic, and electric drive modes and can be designed as various special ceramic valves according to user requirements.

What Are the Advantages of Zirconia Ceramic Lined Ball Valve

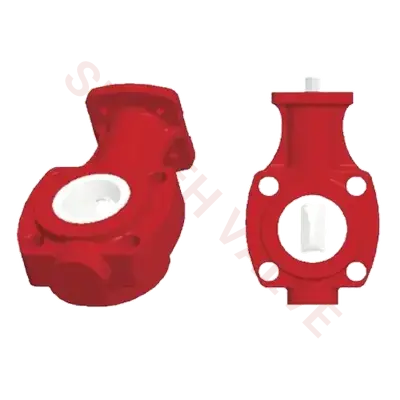

Anti-erosion and wear resistance

The valve ball, valve seat, and lining are all made of zirconia structural ceramic materials with a Rockwell hardness of HRA87 or above, making them capable of withstanding the erosion of high-speed fluid and hard particulate media, thereby exhibiting excellent wear resistance.

Strong corrosion resistance

According to tests conducted by the Institute of Metal Corrosion and Protection, Chinese Academy of Sciences, zirconia ceramic materials possess excellent corrosion resistance, except in glass solutions and hydrofluoric acid.

Long service life

Static pressure life tests conducted by the General Machinery Research Institute of Hefei, Ministry of Machinery, show that there is no leakage even after ten thousand cycles of switching.

Wide application range

Suitable for various acid, alkali, and salt liquid and gas media environments, particularly in hard-sealed valves in environments with particulate and fibrous media.

The Design of Zirconia Ceramic Lined Ball Valve

Zirconia ceramic lined ball valve has a simple structure, and their performance mainly depends on the zirconia material itself. For ring-shaped parts like valve seats, it's important to leverage the advantages of structural ceramics such as wear resistance, erosion resistance, and corrosion resistance, while also addressing the relatively poor toughness compared to metals. Sunyeh has adopted three measures in structural design:

Firstly, considering that ceramic materials have high compressive strength but low tensile toughness, all valve seats are designed with an elastic compensation structure. Through precise calculation of compression and precision machining, the ceramic valve seat can make minor movements as the working pressure changes constantly. The impact force generated by the frequent collision of the valve ball with the valve seat is counteracted through elastic compensation, preventing the valve seat from cracking.

Secondly, within the specified structural length and design space, the size specifications of the ceramic lining and other ceramic components are maximized. By using thicker walls, the structure's strength is improved, its erosion resistance is enhanced, and the overall lifespan and reliability of the ceramic valve are significantly increased.

Thirdly, it is crucial to improve the toughness of ceramics, which is key to the successful application of zirconia ceramic materials in oil pump valve balls and valve seats. Generally, the actual fracture strength of ceramic materials is much lower than the theoretical value. Griffith's brittle fracture theory proposed in 1920, known as the notch strength theory of brittle materials, suggests that internal cracks cause stress concentration, making the stress at the crack tip much higher than the average stress. When the stress at the crack tip reaches the theoretical strength value, the crack rapidly propagates, leading to fracture. Therefore, an effective way to improve ceramic toughness is to prepare dense and pore-free materials and refine the grains to reduce crack sizes. To this end, Sunyeh has established strict production process standards to ensure no cracks or pores are present on the valve ball surface and valve seat sealing surface when products leave the factory.

English

English