Role of Zirconia Ceramic Lined Butterfly Valve

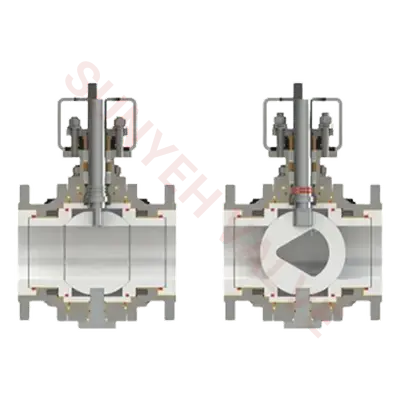

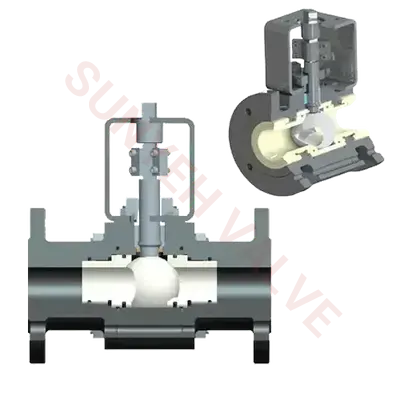

The zirconia ceramic lined butterfly valve is a quarter-turn valve used to regulate or isolate the flow of fluid in a pipeline system. It consists of a disc mounted on a rotating shaft. When the valve is fully open, the disc is parallel to the flow of the fluid, allowing almost unrestricted passage. When the valve is closed, the disc rotates to completely block the flow.

The zirconia ceramic lined butterfly valve is an ideal choice for space-constrained environments due to its compact design and quick operation. They effectively control liquids and gases, making them widely used in various industries such as wastewater treatment, chemical processing, and HVAC systems. This design is easy to install and maintain, providing an efficient solution for flow control in valves.

Advantages of Zirconia Ceramic Lined Butterfly Valve

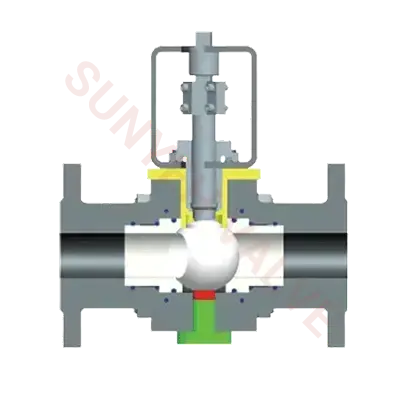

Corrosion Resistance

With stable chemical properties, it can withstand the corrosion of most existing corrosive media.

High Strength

Hardness reaches 87HRA, flexural strength ≥1150 MPa, and fracture toughness up to 35M Pa·m1/2.

Machinability

It has good machinability, allowing for ultra-clean machining, which can significantly reduce the opening torque of ceramic valves.

Thermal Expansion Coefficient

Has a thermal expansion coefficient similar to that of metal materials, enabling synchronization with metal materials in various temperature environments.

Thermal Shock Resistance

Exhibits excellent thermal shock resistance, ΔT(℃) ≥250.

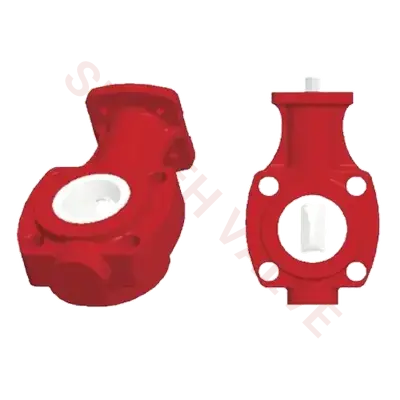

SUNYEH's zirconia ceramic lined butterfly valves are meticulously crafted to ensure they meet the highest industry standards. These valves exhibit superior corrosion and wear resistance, specifically designed for challenging environments.

As a professional butterfly valve manufacturer, SUNYEH focuses on providing high-quality fully-lined and partially-lined ceramic butterfly valves for various industrial applications.

English

English