In the vehicle, ship, and armament manufacturing industry, the normal operation of equipment directly impacts product quality and production efficiency. In this process, control valves, as key components for regulating the flow of media, play a critical role. Their performance directly affects the stability of the entire production line, especially when dealing with a variety of complex conditions involving media such as steam, tap water, natural gas, and seawater, which raise the performance requirements of valves to new heights.

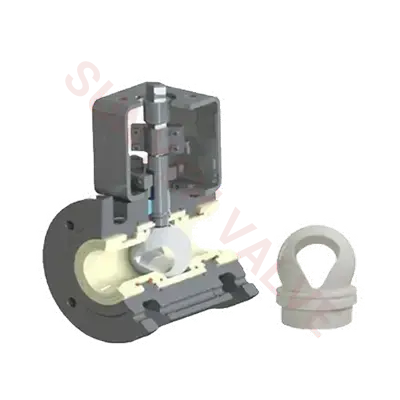

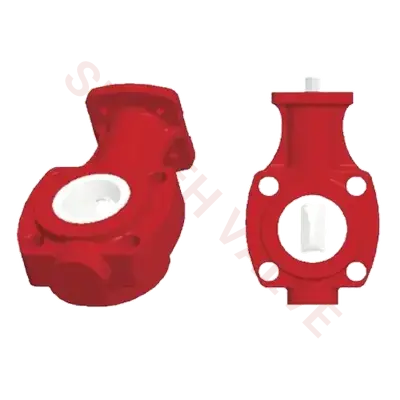

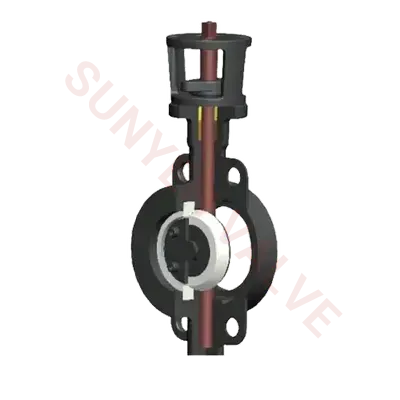

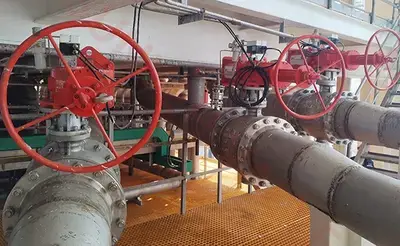

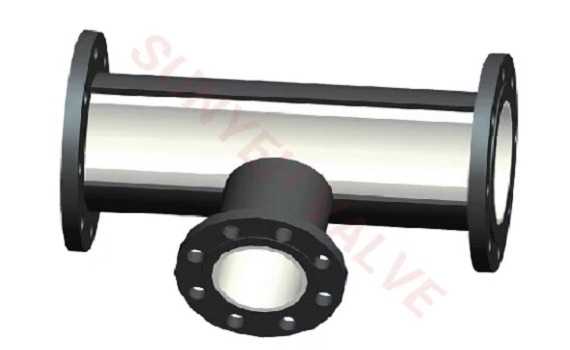

Against this backdrop, Sun Yeh ceramic-lined control valves, with their excellent performance, meet the needs of the vehicle, ship, and armament manufacturing industry. These valves utilize high-performance ceramic materials as linings, which not only exhibit excellent wear and corrosion resistance but also maintain stable performance under extreme conditions such as high temperatures and pressures.

Firstly, steam, a commonly used energy medium in the manufacturing process of vehicles, ships, and armaments, is used for heating and sterilization stages. The steam environment places high demands on valves due to high temperatures and pressures; ordinary metal valves are prone to oxidation and corrosion. For steam conditions, the high-temperature stability of ceramic materials allows Sun Yeh ceramic-lined control valves to withstand long periods of high-temperature steam exposure, keeping the inner walls as smooth as new, significantly reducing the possibility of leakage. Additionally, the excellent thermal conductivity of the ceramic materials aids in heat transfer and dispersion of the valves, preventing local overheating and material degradation, effectively ensuring safety and efficiency in production.

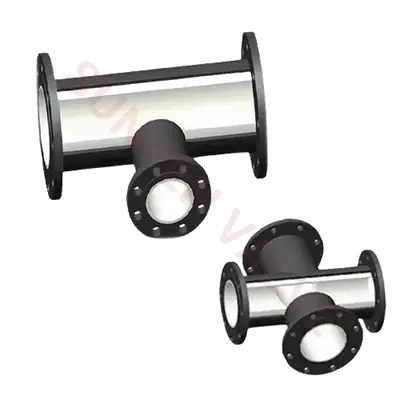

Secondly, the transportation and control of media such as tap water and seawater are essential components of the vehicle and ship equipment manufacturing process. These media may contain various chemicals, posing high demands on the inner walls and sealing performance of the valves. Under tap water and seawater conditions, the non-stick nature of ceramic materials keeps the valve inner walls smooth and clean, effectively preventing microbial growth and chemical corrosion, ensuring the cleanliness of the media and pipelines. Moreover, the wear resistance of ceramic materials ensures that the valve inner walls are not eroded by prolonged contact with water, extending the valve's lifespan.

Furthermore, natural gas, as a clean energy source, is increasingly used in the manufacturing process of vehicles, ships, and armaments. The main requirements for valves in natural gas environments are corrosion resistance and sealing. For natural gas conditions, the excellent sealing performance and corrosion resistance of Sun Yeh ceramic-lined control valves ensure a good seal in high-pressure, highly corrosive environments, preventing natural gas leaks that could pose threats to the environment and production safety.

Finally, it is worth mentioning that in some special production stages, such as deep-sea operations and polar exploration, where equipment needs to operate under extreme conditions, Sun Yeh ceramic-lined control valves maintain good performance under extreme temperatures and pressures, making them a suitable choice for related industries.

In summary, Sun Yeh ceramic-lined control valves play a very important role in the vehicle, ship, and armament manufacturing industry. They not only meet the requirements of various complex conditions but also enhance production efficiency, reduce operating costs, ensure production safety, and protect the environment. Therefore, choosing Sun Yeh ceramic-lined control valves is a wise decision for enterprises in this industry.

English

English