Polycrystalline silicon is an important semiconductor material widely used in photovoltaic cells, integrated circuit chips, and other fields. In the production of polycrystalline silicon, various valves are needed for the transportation and control of raw materials. However, due to the specificity of polycrystalline silicon materials, ordinary metal valves often cannot meet the requirements of its production process. The production process of polycrystalline silicon involves stages such as pneumatic feeding, reactor feeding, granular silicon process, hydrogen chloride process, silicon tetrachloride converter drum, filter slag outlet, final high-pressure storage, and exhaust gas treatment, presenting the following challenges for valves:

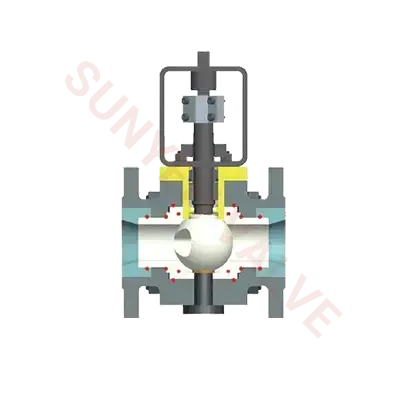

Corrosion Resistance: Chemicals used in the production of polycrystalline silicon, such as hydrogen chloride (HCl), are extremely corrosive. Sun Yeh ceramic-lined valves can resist these strong acidic and alkaline conditions, ensuring the inner walls of the valves are protected from damage, thereby extending their service life.

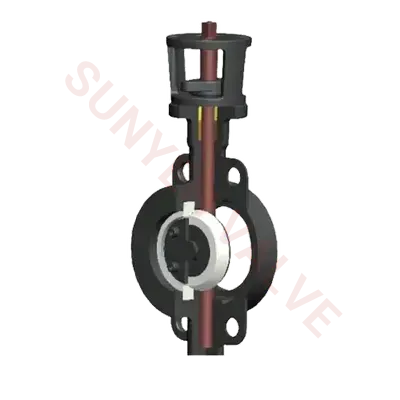

Wear Resistance: In stages like the granular silicon process, friction between solid particles and valve surfaces can cause rapid wear. The high hardness and good wear resistance of Sun Yeh ceramic materials make them an ideal choice, reducing maintenance frequency and replacement costs.

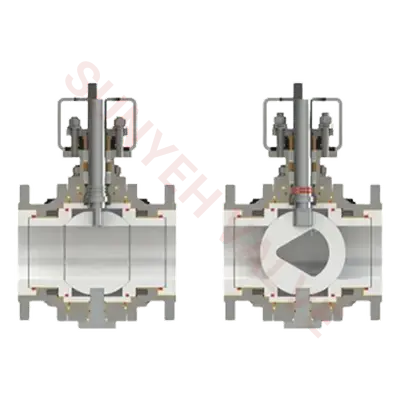

High Sealing Performance: To prevent harmful gases from leaking into the environment or causing losses during production, valves must have excellent sealing capabilities. Sun Yeh ceramic-lined valves provide reliable sealing effects, ensuring process safety.

Wide Temperature Range: The chemical reactions and material handling involved in the production of polycrystalline silicon often occur under high or low-temperature conditions. Sun Yeh ceramic-lined valves can adapt to these extreme temperature changes, maintaining normal operation.

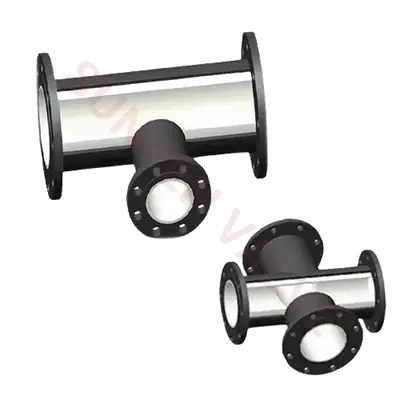

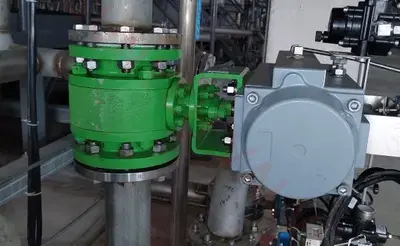

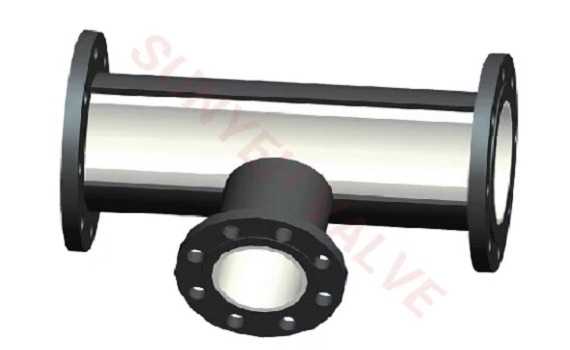

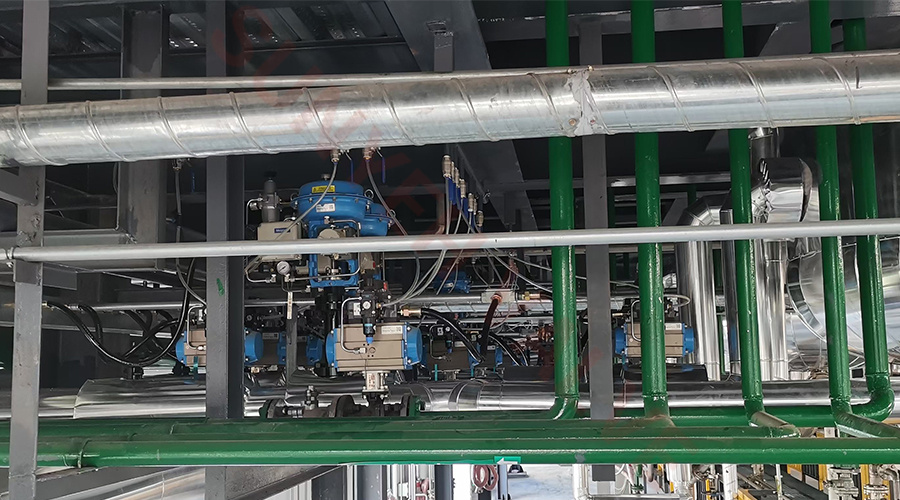

In practical applications, Sun Yeh ceramic-lined valves are used in key positions in various polycrystalline silicon production lines, including but not limited to:

Piping systems equipped with chemical pipelines;

Inlet and outlet ports of reactors, to prevent chemical damage to equipment;

High-temperature areas, such as connections between reduction furnaces and top furnaces;

Exhaust gas treatment systems.

In summary, Sun Yeh ceramic lined valves, with their corrosion resistance, wear resistance, high sealing performance, and stability across a wide temperature range, provide a safe and economical solution in the polycrystalline silicon industry.

English

English