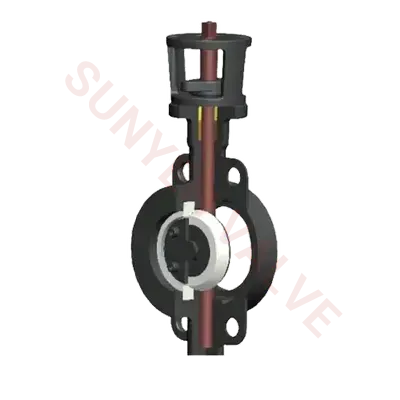

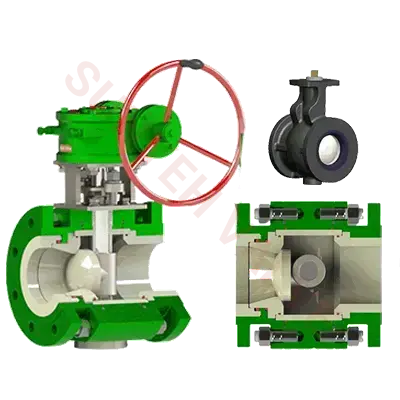

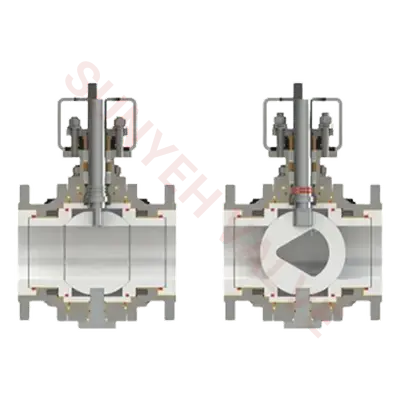

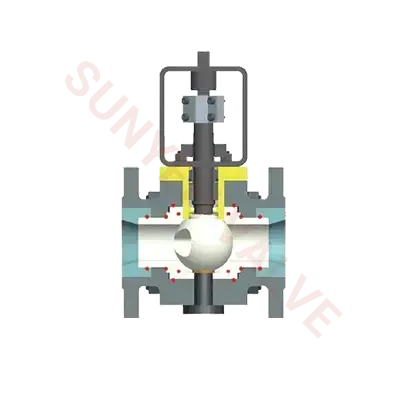

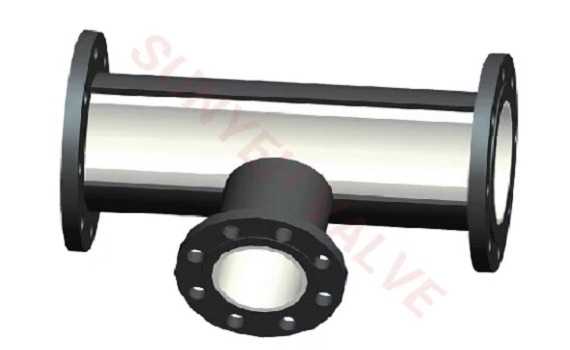

Sun Yeh ceramic-lined valves, renowned for their exceptional corrosion resistance and wear resistance, have been widely applied in the chlor-alkali industry. In this industry, the production media are typically highly corrosive alkaline or acidic substances. Traditional metal valves under these harsh conditions are prone to severe corrosion, leading to leaks and wear, necessitating frequent replacements. This not only increases operational costs but also poses potential threats to environmental and worker safety due to leaks. For instance, in the production of caustic soda, the emulsified medium of heavy soda contains particles, rocks, and lime milk, which are highly corrosive, viscous, prone to clogging, and cause significant wear. Ordinary valves often fail quickly due to severe corrosion, substantial leaks, and poor regulatory performance.

In contrast, Sun Yeh ceramic lined valves can withstand these harsh conditions without significant physical or chemical degradation, thus significantly extending their service life and reducing maintenance needs. Furthermore, these valves also exhibit excellent high-temperature resistance, with some models operating normally at temperatures up to 500°C, which is crucial for many high-temperature processes in the chlor-alkali industry.

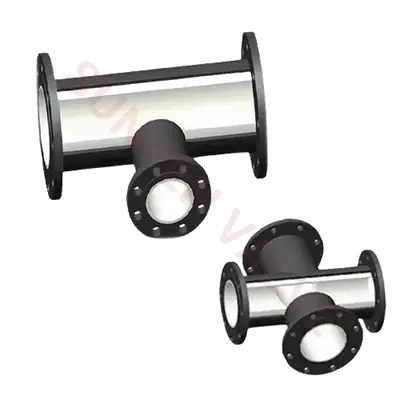

In practical applications, Sun Yeh ceramic-lined valves have been extensively used in the chlor-alkali industry to regulate the transport of substances such as calcium carbide pulp, caustic soda, stabilizers, dispersants, liquid chlorine, brine, and mother liquor. The ceramic lining enhances the valves' corrosion resistance and high-temperature capabilities, thereby improving the production efficiency and safety of the entire chlor-alkali industry.

Overall, Sun Yeh ceramic-lined valves offer an economically efficient and environmentally friendly solution for the chlor-alkali industry, addressing the unique engineering challenges encountered in the production of heavy alkali. By reducing maintenance costs and downtime, these valves help enhance production efficiency while minimizing potential environmental impacts, thus supporting sustainable industrial practices.

English

English