Electric ceramic ball valves are widely used in fields such as thermal power plants and chemical plants, especially in wet flue gas desulfurization systems, where they play a crucial role. Due to the presence of a large amount of harmful gases in the flue gas, such as sulfur dioxide and hydrogen fluoride, the desulfurization process requires special valve fittings to cope with highly corrosive and high-wear environments. Electric ceramic ball valves, with their excellent wear resistance and corrosion resistance, have become the ideal valve choice in these fields.

Electric Ceramic Ball Valves: Excellent Corrosion Resistance

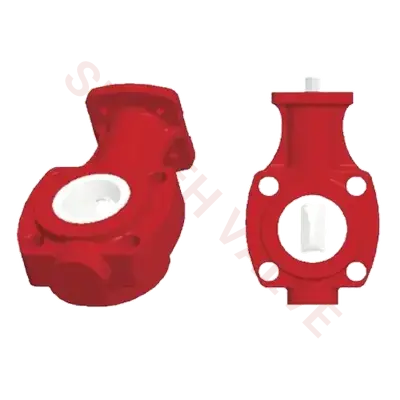

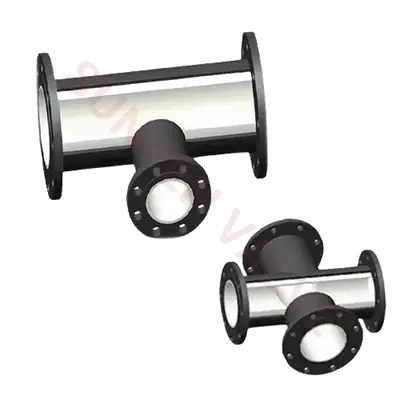

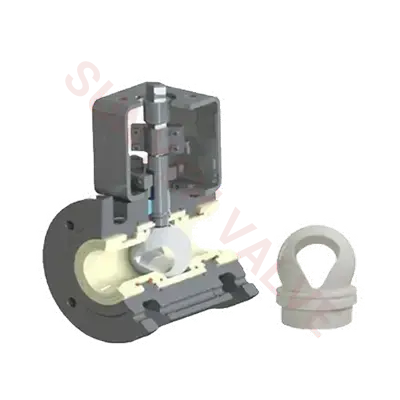

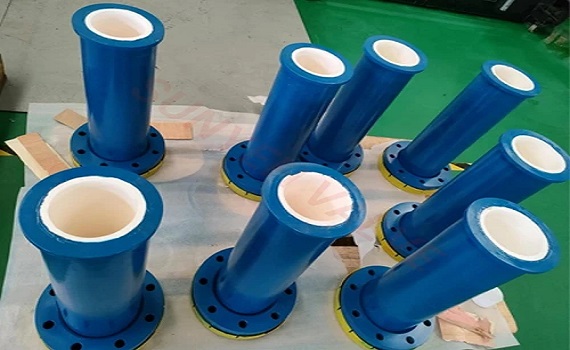

The valve ball, valve seat, and valve body lining of electric ceramic ball valves are all made of high-hardness, high-strength structural ceramic materials. These ceramic materials have excellent chemical inertness, effectively resisting the corrosion of acidic gases, lime water, and gypsum slurry. In desulfurization and denitrification systems, the presence of corrosive liquids often damages ordinary valves, but electric ceramic ball valves can maintain good performance in harsh working environments, significantly reducing maintenance costs caused by corrosion.

Electric Ceramic Ball Valves: Superior Wear Resistance

The valve core part of electric ceramic ball valves is made of structural ceramic materials with extremely high hardness, which can effectively combat the wear caused by solid particles in lime slurry. During the desulfurization process in power plants, the flow speed and high corrosiveness of the lime slurry can cause severe wear on valves. Electric ceramic ball valves utilize the high hardness of ceramic materials, and through the shearing action between the valve ball and valve seat, they can shred solid particles in the medium, preventing wear damage to the valve and ensuring long-term stable operation.

Electric Ceramic Ball Valves: Enhance System Stability

Due to the wear resistance and corrosion resistance of electric ceramic ball valves, they exhibit significant stability in desulfurization and denitrification systems. The corrosiveness and abrasiveness of lime water and gypsum slurry in power plant desulfurization systems pose huge challenges to valves. However, electric ceramic ball valves, through their excellent performance, can effectively extend the service life of the valves, reduce failure occurrences, lower maintenance costs, and ensure long-term stable operation of the system.

Electric Ceramic Ball Valves: Reduce Maintenance Costs

After using electric ceramic ball valves, the maintenance costs for power plants are significantly reduced. Traditional valves, when faced with highly corrosive and high-wear environments, require frequent replacement and repairs. The wear-resistant and corrosion-resistant characteristics of electric ceramic ball valves allow them to maintain a low failure rate during long-term operation, thus reducing the costs of replacement and downtime and improving production efficiency.

Electric ceramic ball valves play an important role in power plant desulfurization and denitrification systems. With their superior corrosion resistance and wear resistance, they effectively enhance the stability of the system and reduce maintenance costs. For highly corrosive and high-wear environments such as flue gas desulfurization, choosing electric ceramic ball valves can significantly improve the reliability and durability of equipment, ensuring the efficient operation of production systems.

English

English