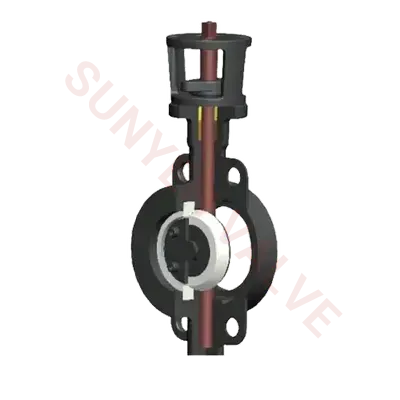

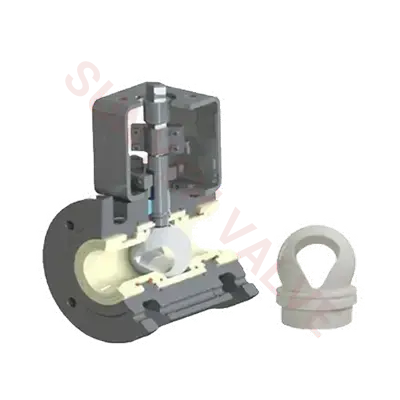

The mining industry frequently faces significant wear and corrosion issues during the extraction, transportation, and processing of ores. Traditional valves are prone to damage under high-intensity usage, affecting production efficiency and safety. Anti-abrasion fixed valves, with their excellent wear resistance and strength, have become one of the key pieces of equipment in mining.

Anti-Abrasion Fixed Valves: Enhancing Slurry Transportation Efficiency

During slurry transportation, the solid particles in the slurry exacerbate valve wear. Anti-abrasion fixed valves, with their strong wear resistance, can effectively reduce valve loss, ensure the stable operation of the pipeline system, and help mining enterprises increase slurry transportation efficiency.

Anti-Abrasion Fixed Valves: Extending Lifespan

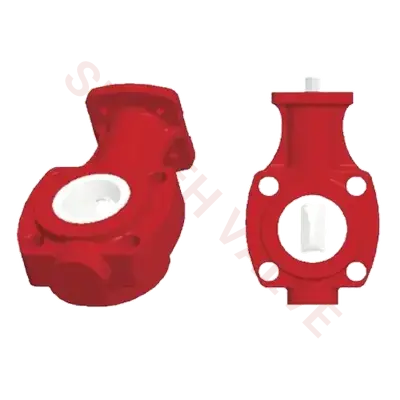

Equipment in mining frequently faces extreme conditions, with valves often switching and exposed to high temperatures and corrosive environments. Anti-abrasion fixed valves use special materials and designs, featuring remarkable corrosion and high-temperature resistance, thereby extending the service life of the equipment, reducing the frequency of maintenance and replacement, and lowering operating costs.

Anti-Abrasion Fixed Valves: Enhancing Safety

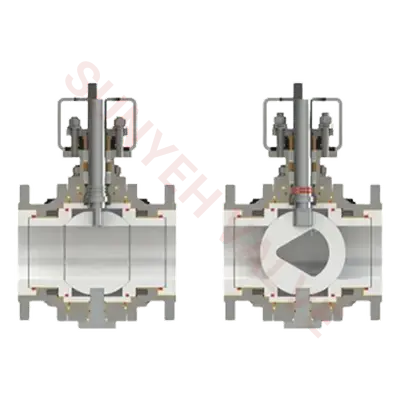

Anti-abrasion fixed valves can maintain good sealing in high-pressure or high-temperature environments, preventing leaks and safety hazards in mining production. Their excellent wear resistance and sealing performance ensure the safe operation of mines.

Anti-Abrasion Fixed Valves: Improving Production Stability

Valves in mining frequently operate, and anti-abrasion fixed valves can withstand high-frequency opening and closing operations, reducing downtime caused by equipment failures. They ensure the continuous and stable operation of mining production lines, thereby enhancing the stability of the production process.

Anti-Abrasion Fixed Valves: Coping with Complex Conditions

The mining production environment is complex, and anti-abrasion fixed valves can work efficiently under various fluid, temperature, and pressure conditions. Whether in ore crushing, mineral processing, or slurry transportation, they can stably control operations, reducing the demand for different valves and lowering equipment maintenance costs.

The application of anti-abrasion fixed valves in mining, by enhancing transportation efficiency, extending equipment lifespan, improving system safety, increasing production stability, and coping with complex conditions, reliably guarantees mining production, making them a key piece of equipment.

English

English