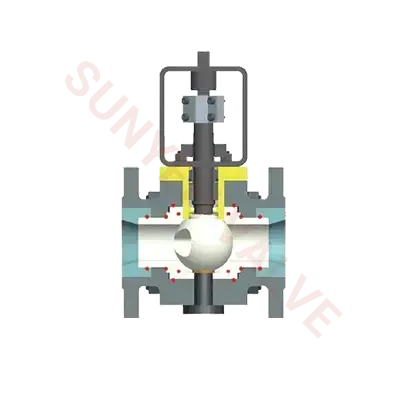

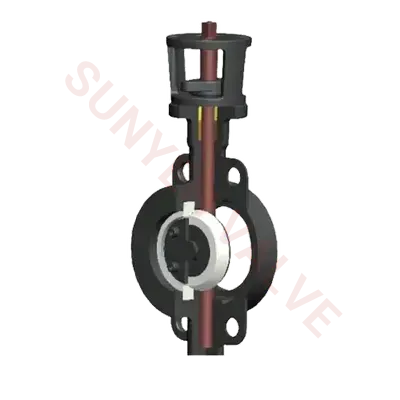

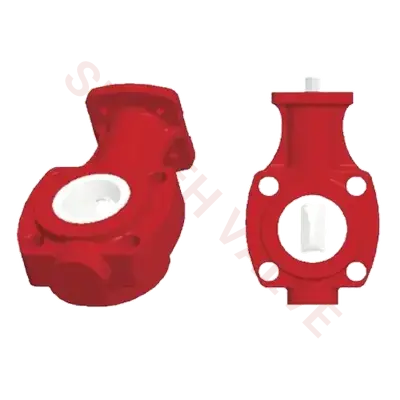

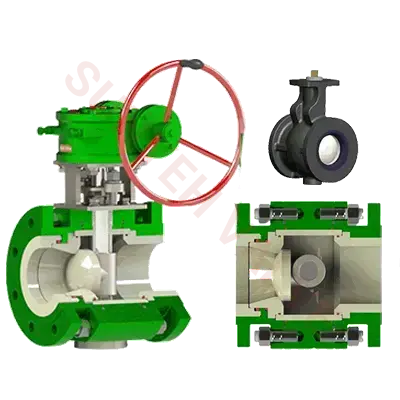

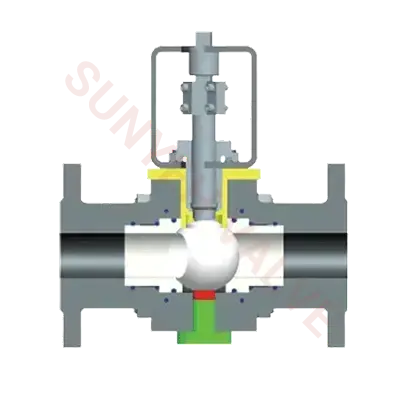

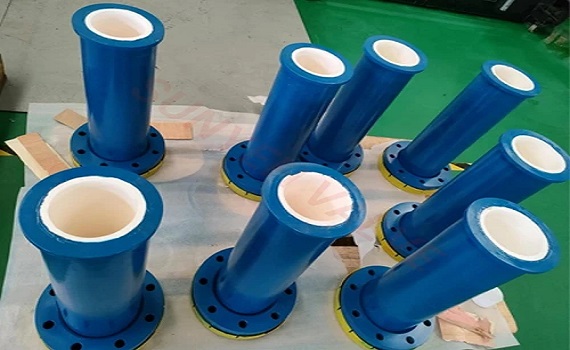

Ceramic lined valves, including ceramic lined ball valves and ceramic butterfly valves, are essential components in various industries such as chemical, petrochemical, and power generation. These valves are known for their exceptional resistance to wear, corrosion, and abrasion, making them ideal for handling abrasive and corrosive fluids. However, like any other industrial equipment, ceramic lined valves require proper maintenance and care to ensure optimal performance and longevity. In this blog, we will discuss five effective ways to extend the lifespan of ceramic lined valves and ensure their reliable operation.

1. Regular Inspection and Maintenance

Regular inspection and maintenance are crucial for extending the lifespan of ceramic lined valves. Inspecting the valves for wear, leaks, and other signs of damage can help identify potential issues early on and prevent costly repairs or replacements. It is recommended to establish a maintenance schedule and adhere to it diligently to keep the valves in optimal condition.

2. Proper Installation and Operation

Proper installation and operation are key factors in maximizing the lifespan of ceramic lined valves. Ensure that the valves are installed correctly according to the manufacturer's guidelines and industry standards. Improper installation can lead to leaks, premature wear, and reduced lifespan. Additionally, operate the valves within their specified parameters to prevent unnecessary stress and damage.

3. Use Compatible Fluids

Using compatible fluids is essential for the longevity of ceramic lined valves. Make sure that the valves are only exposed to fluids that are compatible with the ceramic lining material. Avoid using abrasive or corrosive fluids that can degrade the ceramic lining and compromise the valve's performance. Consult with the valve manufacturer or a fluid compatibility expert to determine the appropriate fluids for your specific application.

4. Implement Proper Cleaning Procedures

Cleaning ceramic lined valves regularly is important for maintaining their performance and extending their lifespan. Use gentle cleaning methods and avoid harsh chemicals or abrasive tools that can damage the ceramic lining. Follow the manufacturer's recommendations for cleaning procedures and use suitable cleaning agents to remove deposits and contaminants effectively.

5. Choose High-Quality Valves from a Reputable Manufacturer

Selecting high-quality ceramic lined valves from a reputable manufacturer, such as SUN YEH, can significantly impact their lifespan and performance. SUN YEH is a trusted brand known for producing durable and reliable valves that meet stringent quality standards. Investing in high-quality valves from a reputable manufacturer can help ensure long-term performance and minimize the risk of premature failure.

In conclusion, extending the lifespan of the ceramic lined valve requires a proactive approach to maintenance, proper installation and operation, the use of compatible fluids, implementing proper cleaning procedures, and choosing high-quality valves from a reputable manufacturer like SUN YEH. By following these five effective ways, you can maximize the longevity of ceramic lined valves and ensure their reliable operation in various industrial applications.

English

English