Operating Conditions and Environment

When selecting ceramic ball valves, it's crucial to consider the specific operating conditions and environment in which the valves will be used. Factors such as temperature, pressure, fluid type, and potential exposure to corrosive or abrasive substances should all be taken into account. Ceramic ball valves are known for their excellent resistance to corrosion, wear, and high temperatures, making them suitable for demanding applications in industries such as chemical processing, petrochemical, and power generation.

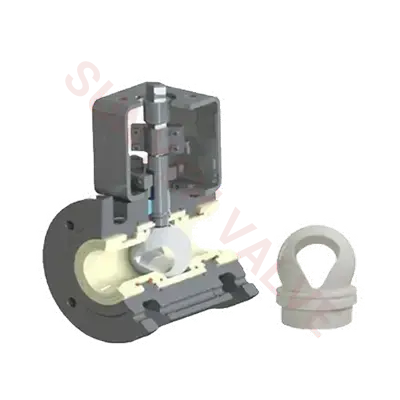

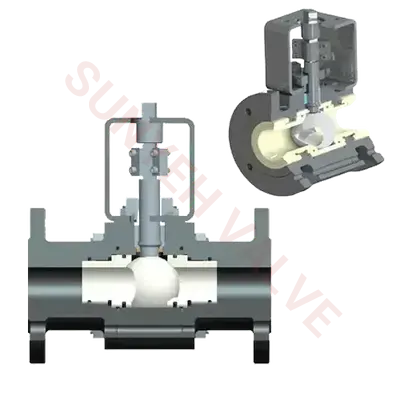

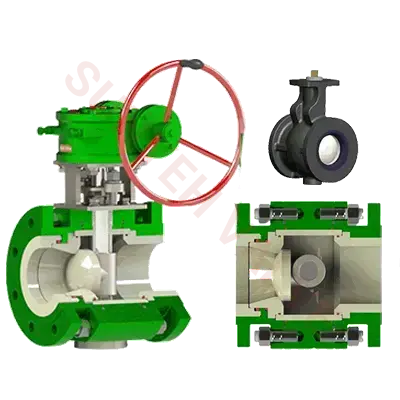

Material Composition and Properties

Ceramic ball valves are typically constructed from advanced ceramic materials such as alumina (aluminum oxide) or zirconia (zirconium oxide). These materials offer exceptional hardness, corrosion resistance, and thermal stability. When selecting ceramic ball valves, it's essential to consider the specific properties of the ceramic material used, as well as its compatibility with the intended application. Different ceramic compositions may offer varying levels of performance in terms of wear resistance, thermal conductivity, and chemical compatibility.

Flow Rate and Pressure Drop

The flow rate and pressure drop requirements of the application are critical factors to consider when selecting ceramic ball valves. Valves must be appropriately sized to ensure efficient flow control and minimal pressure drop across the system. Ceramic ball valves are available in various sizes and configurations to accommodate different flow rates and pressure conditions. It's essential to choose a valve size and type that meets the specific flow control requirements of the application while minimizing energy consumption and optimizing system performance.

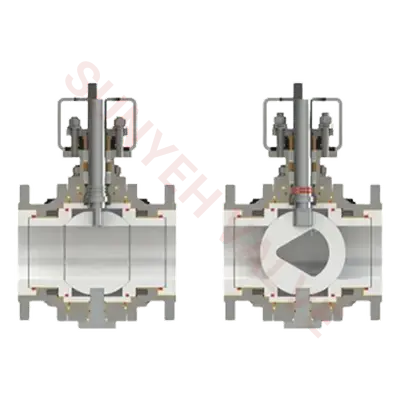

Sealing Performance and Leakage Prevention

Effective sealing is essential for ensuring the reliable operation of ceramic ball valves and preventing leakage in fluid control systems. Ceramic ball valves are known for their tight shut-off capabilities and minimal leakage rates. Factors such as the design of the valve seats, the quality of the sealing surfaces, and the precision of the manufacturing process all contribute to the sealing performance of ceramic ball valves. When selecting a ceramic ball valve, it's essential to consider these factors to ensure leak-free operation and compliance with industry standards and regulations.

Maintenance Requirements and Lifecycle Considerations

Finally, when selecting ceramic ball valves, it's essential to consider the maintenance requirements and lifecycle considerations of the valves. While ceramic ball valves offer excellent resistance to corrosion and wear, they may still require periodic maintenance and inspection to ensure optimal performance and longevity. Factors such as ease of maintenance, availability of spare parts, and the expected lifecycle of the valves should all be taken into account when selecting ceramic ball valves for long-term use in industrial applications.

In conclusion, several factors should be considered when selecting ceramic ball valves for fluid control applications. By carefully evaluating factors such as operating conditions, material composition, flow rate, sealing performance, and maintenance requirements, industries can choose ceramic ball valves that meet their specific needs and ensure reliable and efficient operation in demanding environments.

en

en  es

es  ru

ru  ar

ar  tr

tr  id

id