After 1-2 years of application, the ceramic-lined pipes are opened for observation and precise measurement, and the composite layer shows no significant wear or peeling. In terms of the same specifications and unit length of the pipe, the weight of ceramic-lined pipes is only about 1/2 of that of cast steel pipes or steel wire mesh skeleton pipes, reducing the per meter engineering budget by 30-40%. It is only about 2/5 of the weight of cast stone pipes and wear-resistant steel pipes, reducing the per meter engineering budget by more than 20%.

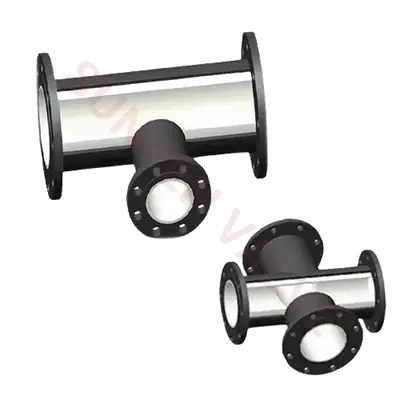

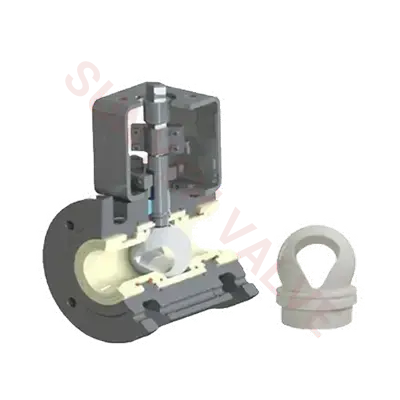

The production process of Sunyeh ceramic chip wear-resistant pipes involves workers using high-temperature-resistant strong adhesive to stick wear-resistant ceramic pieces (92 porcelain/95 porcelain) onto the inner wall of the pipe. After heating and curing, a firm wear-resistant layer is formed, and the inner wall is visibly white. The ceramic ring wear-resistant pipes are made by installing ceramic rings, produced using isostatic pressing technology, in ordinary steel pipes or stainless steel pipes to form ceramic ring wear-resistant ceramic pipes.

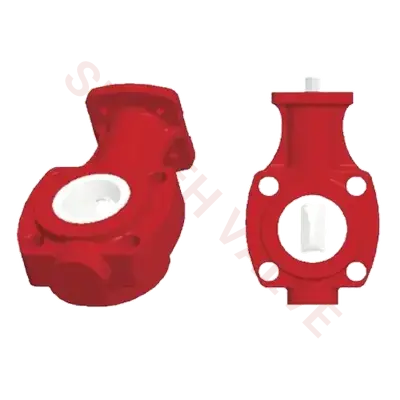

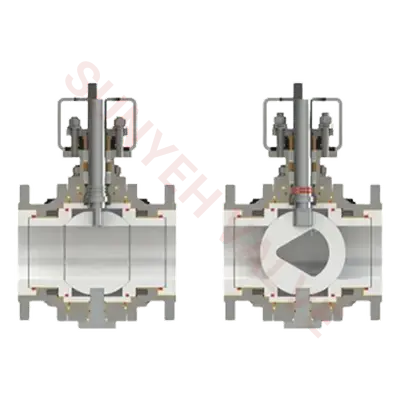

What Forms Do Ceramic Lined-pipes Come In?

They can generally be divided into the following four types:

Features of Sunyeh Ceramic Lined-pipe

High hardness

Rockwell hardness HRA>85, Mohs 9, hardness second only to diamond, far surpassing the wear resistance of wear-resistant steel and stainless steel.

High wear resistance

Ceramic wear resistance is equivalent to 266 times that of manganese steel, and 171.5 times that of high chromium cast iron.

Lightweight

Ceramic chip density >3.6g/cm3, only half the weight of steel, which can greatly reduce equipment load.

High ceramic purity

Two materials are available, with alumina content of 99.5% and 999.9%.

In conclusion, Sunyeh ceramic-lined pipes fully leverage the high compressive strength, good ductility, impact resistance, and good welding properties of steel pipes, as well as the high hardness, super wear resistance, corrosion resistance, and high-temperature resistance of corundum ceramics. They overcome the low strength and poor wear resistance of steel pipes and the poor ductility of ceramics.

English

English