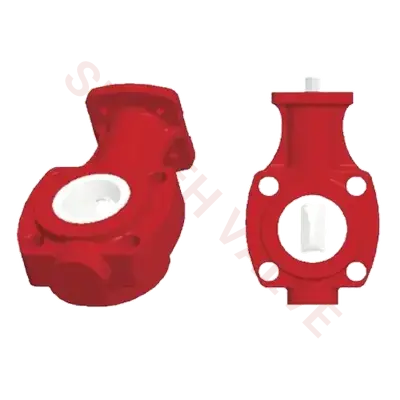

The Excellence of Ceramic Lined Valves

The basic functions of valves include cutting off and turning on the medium, regulating flow, and changing direction, playing a controlling and regulating role in pipeline systems. Although metal valves have a history of over a century and have been improved, they face limitations due to the properties of metal materials. In special environments with high wear and strong corrosion, metal valves often exhibit poor sealing, short service life, and frequent leakage, affecting system stability. With the development of the chemical industry, the requirements for valves in specific engineering tasks are continuously increasing. Ceramic lined valves have thus emerged, offering high strength, wear resistance, corrosion resistance, and high-temperature resistance. These excellent properties allow ceramic lined valves to maintain outstanding stability and mechanical performance in harsh environments.

Specific Advantages of Ceramic Lined Valves

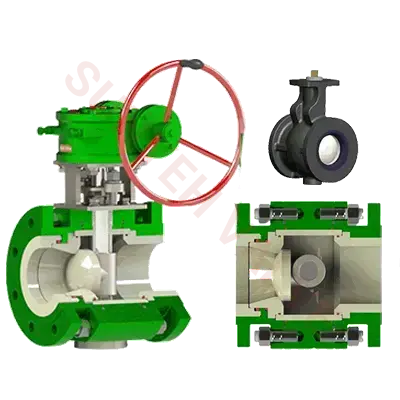

Long Service Life

Compared to valves made of other materials, ceramic lined valves demonstrate an extremely long effective service life in high-temperature and high-pressure working environments. This not only ensures the normal operation of the chemical transportation industry to a certain extent but also reduces the cost of chemical production and improves the working efficiency of valves.

Wide Range of Applications

Ceramic lined valves have a wide range of applications, including power generation, chemical industry, metallurgy, and mining. In addition, they are also used in industrial fields such as sewage treatment.

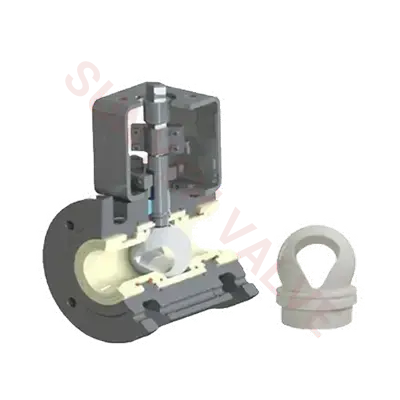

Mature Manufacturing Process

With the continuous innovation and development of technology, the manufacturing process and procedures for ceramics have become increasingly mature and refined. Important process links such as ceramic product formulation, processing, and molding have improved due to the application of new technologies.

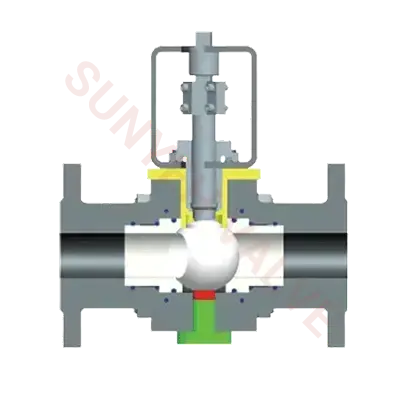

Wide Source of Raw Materials

The raw materials for manufacturing ceramic-lined valves are relatively abundant. By utilizing materials containing elements like aluminum and silicon and processing them, they can be used to produce ceramics.

Superior Performance

Ceramic lined valves exhibit superior performance in high temperature, wear resistance, and corrosion resistance compared to other types of valves. Additionally, they have good sealing and thermal conductivity properties.

Low Manufacturing Cost

The choice of raw materials for producing ceramics is relatively common, saving a significant amount of rare metal resources. Moreover, the application of ceramic lined valves can effectively reduce the labor intensity of workers, result in stable system operation, and lower the expenses related to system maintenance and valve replacement, effectively saving on usage costs. The sealing surface and the parts in contact with the fluid in ceramic lined valves have very high hardness (Rockwell HRA≥88, equivalent to Rockwell HRC≥70). Ceramic lined valves are stable in performance and have excellent self-lubrication, resulting in very small torque and facilitating remote control.

English

English