What Is a Ceramic Butterfly Valve

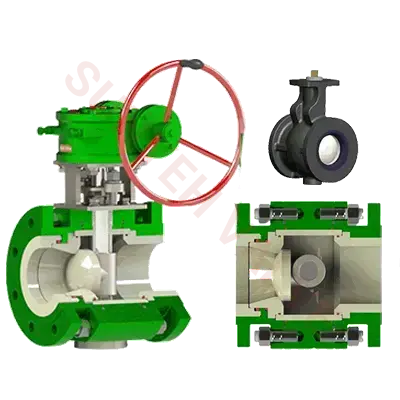

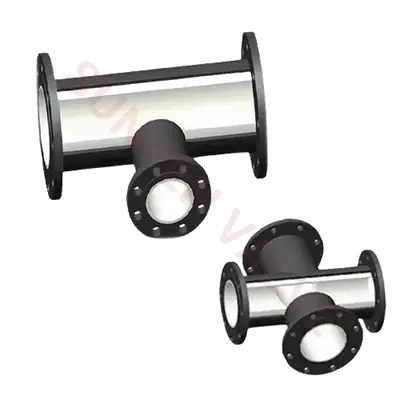

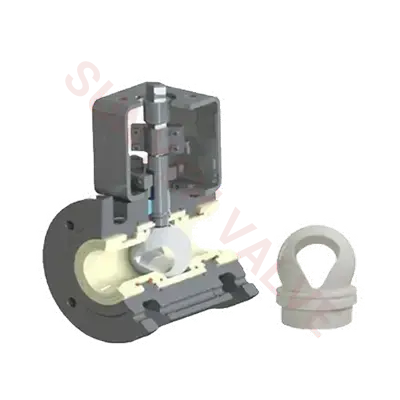

A ceramic butterfly valve is a type of butterfly valve made with ceramic material as the lining. It differs from ordinary metal butterfly valves; the key feature of Sunyeh's ceramic butterfly valve is the use of ceramic material to enhance its corrosion resistance and wear resistance.

Features of Sunyeh Ceramic Butterfly Valve

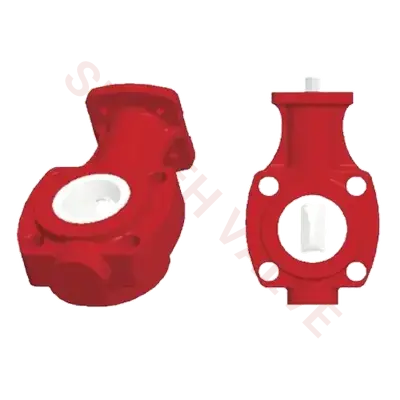

The ceramic butterfly valve adopts an eccentric structure, reducing friction in moving parts. It has a compact structure, small size, light weight, flexible operation, small operating torque, and is labor-saving and energy-efficient. It is suitable for harsher working conditions, costs low, has a long service life, and offers high cost-performance. It has excellent corrosion resistance, high temperature resistance, wear resistance, erosion resistance, magnetic resistance, and antistatic properties. It can be paired with valve components made of different materials according to various working conditions. It comes with manual, pneumatic, electric, and other driving methods, with complete models to meet different customer needs.

Strong corrosion resistance: Ceramic butterfly valves are made of ceramic material, which has excellent corrosion resistance, allowing them to work stably for a long time in corrosive media such as acid, alkali, and salt, without undergoing corrosive reactions.

Good wear resistance: Ceramic material has a very high hardness, effectively resisting wear and scratches. The sealing parts of ceramic butterfly valves are made of ceramic material, thus providing good wear resistance, allowing stable operation for a long time.

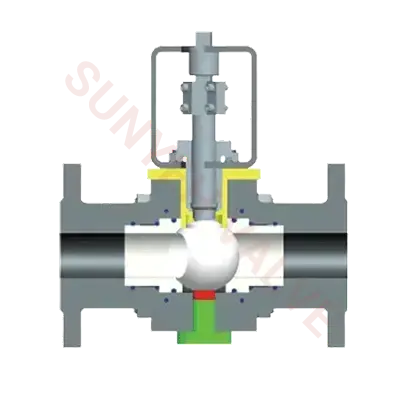

Good sealing performance: Ceramic butterfly valves have excellent sealing performance, ensuring zero leakage. When closed, the ceramic butterfly valve can completely cut off the fluid, ensuring no leakage of the medium.

Superior regulating performance: Ceramic butterfly valves have good regulating performance. By adjusting the valve opening, the flow rate of the fluid can be precisely controlled, providing excellent flow control capabilities.

Working Principle of Ceramic Butterfly Valve

The working principle of a ceramic butterfly valve is similar to that of a general butterfly valve. The valve mainly consists of a valve body, a valve plate (also known as a butterfly plate), and a valve seat. By rotating the valve stem, the valve plate rotates about 90° to control the flow and cut-off of the medium.

Application Fields of Ceramic Butterfly Valve

Ceramic butterfly valves are widely used in industries such as fine chemicals, power, and food.

In summary, Sunyeh ceramic butterfly valves, with their excellent corrosion resistance and wear resistance, play an important role in the cut-off and regulation of corrosive and high-temperature media and are widely used in many industries.

English

English