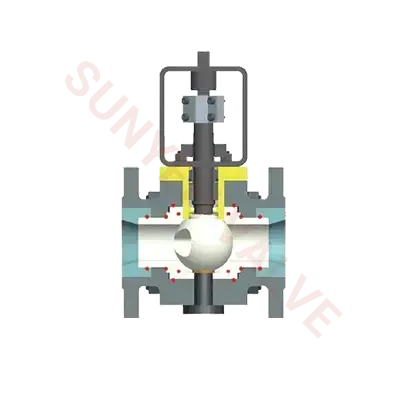

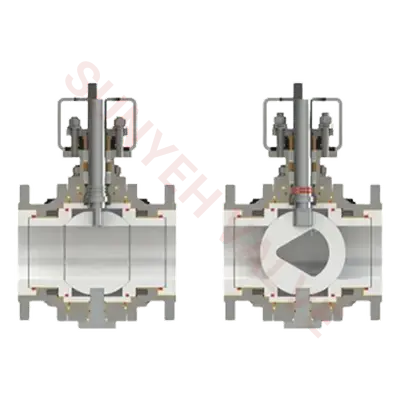

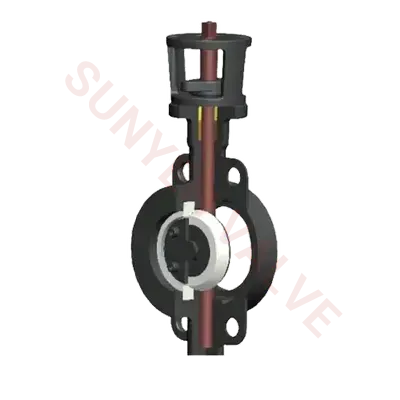

Sunyeh ceramic ball valves adopt high-tech new ceramic structural materials for manufacturing the sealing components and easily worn-out parts of the valve. This improves the valve's wear resistance, corrosion resistance, and sealing properties, significantly extending the valve's service life. The use of ceramic valves can greatly reduce the frequency of valve maintenance and replacement, increase the safety and stability of supporting equipment running systems, and save on equipment repair costs.

Advantages of Ceramic Ball Valves

Simple structure, convenient manufacturing and maintenance.

Small working stroke and short opening and closing time.

Good sealing, low friction between sealing surfaces, and long lifespan.

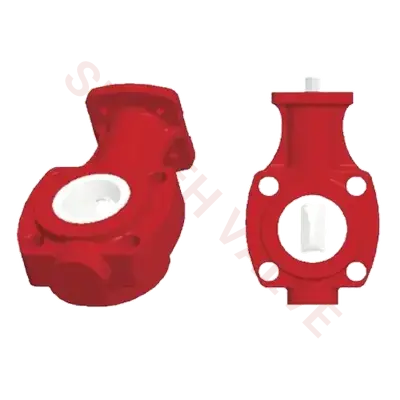

Features of Ceramic Ball Valves

All parts that come into contact with the medium are made of structural ceramic materials, which have extremely high chemical stability and hardness (Rockwell hardness HRC90), second only to diamond. Therefore, this valve has extremely high wear resistance, corrosion resistance, erosion resistance, good thermal insulation, and low thermal expansion.

The Sunyeh ball is manufactured using advanced grinding equipment and processes, resulting in high spherical accuracy and good surface quality. After matching with the valve seat, the self-lubricating property of the ceramic is utilized to achieve excellent sealing performance.

Completely overcomes the disadvantages of metal hard-sealed ball valves, such as easy leakage, high torque, and poor corrosion resistance of the sealing surface.

The excellent wear resistance of ceramic makes this valve durable and highly reliable. Its service life is 2-4 times that of titanium alloy valves and Monel valves.

For mediums with high hardness particles, or mediums that have soft particles but are also corrosive, this type of valve has unparalleled absolute advantages and is the only suitable valve for such mediums.

Working Principle of Ceramic Ball Valves

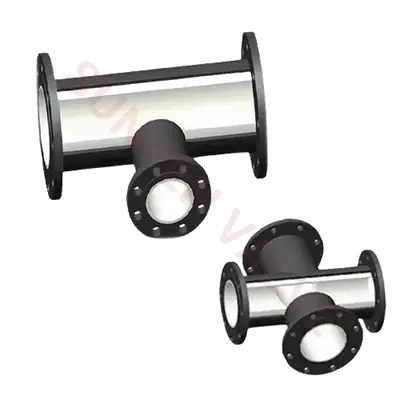

The internal valve core components of Sunyeh ceramic ball valves adopt toughened alumina or zirconia, silicon carbide, and silicon nitride. These materials have extremely high chemical stability and hardness, extremely high wear resistance, corrosion resistance, erosion resistance, good thermal insulation, low thermal expansion coefficient, high hardness, and high electrical insulation properties, outperforming other materials in performance.

Installation Notes for Ceramic Ball Valves

When operating manual valves, an appropriate wrench should be selected. It is strictly forbidden to use a large wrench for small valves, a small wrench for large valves, or to add extension arms to the wrench.

When operating the valve, stand to the side of the valve handwheel. It is strictly prohibited to operate facing the valve stem directly to prevent the medium in the pipe from leaking from the valve packing and causing injury.

When using a wrench to operate manual valves, the wrench and valve handwheel must be securely fastened before operation to prevent slipping and causing injury (especially when standing on potentially slippery surfaces).

Use arm strength for operation, relying on body weight is strictly prohibited to prevent the wrench from slipping and causing falls.

English

English