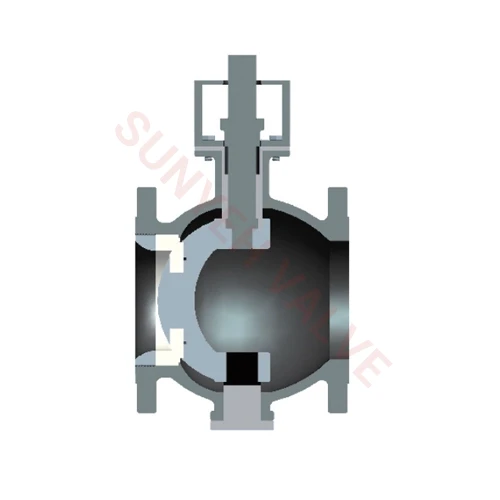

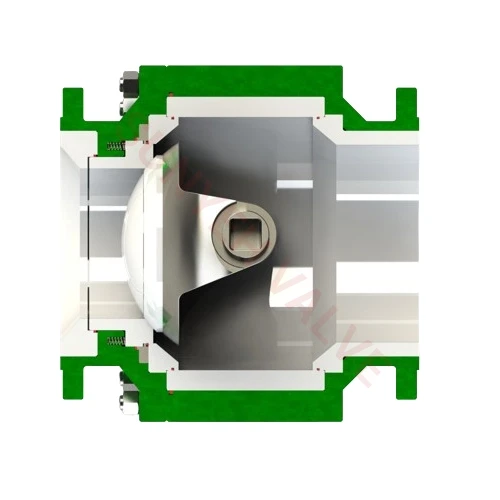

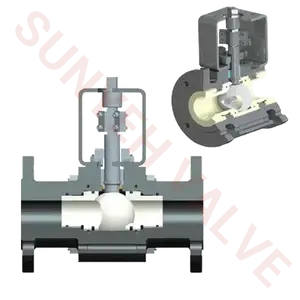

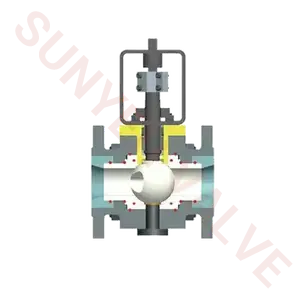

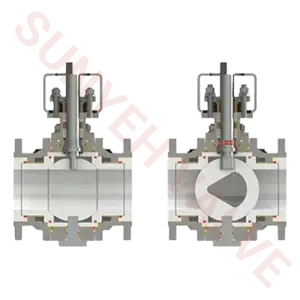

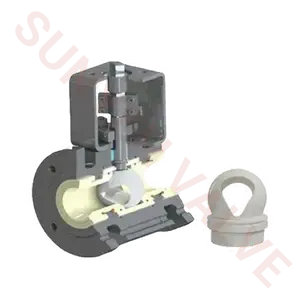

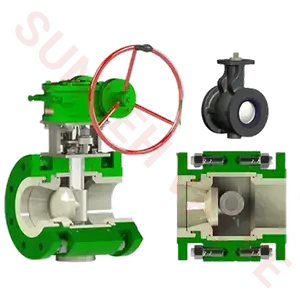

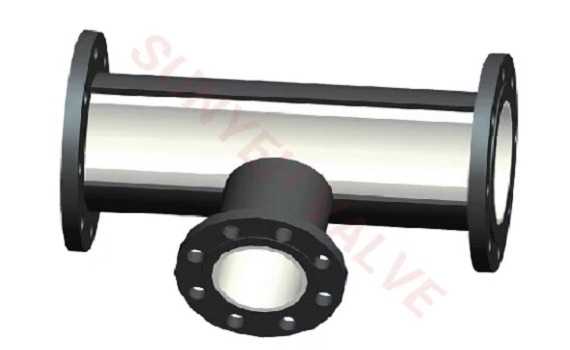

Ceramic lined C-type ball valves are specially designed valves that have a ceramic lined internal structure, a structure that makes them excellent at handling highly abrasive, high temperature, high pressure and corrosive media. The design of a C-type valve usually refers to the shape of the valve, which can be a ball valve, a gate valve, or other types of valves in which the internal passages are in the shape of a C. The design of a C-type valve is often referred to as the shape of the valve.

Ceramic lined C-type ball valves are widely used in the following fields:

1. Power industry: In the desulfurization system of coal-fired power plants, C-type ball valves can handle limestone slurry, which is highly abrasive and corrosive.

2. Chemical industry: In the process of chemical production, C-type ball valves can be used to convey corrosive liquids containing solid particles, such as acids, alkalis, and other chemicals.

3. Metallurgical industry: In the process of ore treatment and smelting in the metallurgical industry, C-type ball valves can resist the erosion of high temperature and abrasive substances.

4. Environmental Protection Industry: In sewage treatment and waste treatment facilities, C-type ball valves can handle wastewater containing solid impurities and prevent pipe blockage and equipment damage.

The advantage of ceramic lined C-type ball valves is their excellent wear and corrosion resistance, which enables them to operate stably for long periods of time under extreme working conditions. In addition, the high hardness and abrasion resistance of ceramic materials help reduce maintenance costs and downtime.

When selecting and using ceramic lined C-type ball valves, you need to consider factors such as the specific nature of the medium, operating temperature, pressure, and flow rate to ensure the performance and safety of the C-type ball valves. At the same time, regular maintenance and inspection are also the key to ensure the long-term stable operation of the C-type ball valves.

English

English