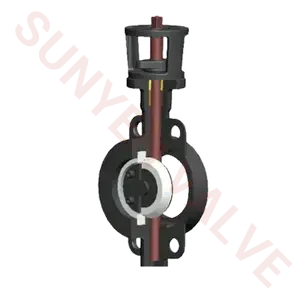

Selecting the right ceramic lined butterfly valve involves several critical considerations to ensure optimal performance in harsh environments. Firstly, assess the properties of the media, including its abrasiveness, chemical composition, and temperature. This assessment will guide the selection of the ceramic material and the valve design best suited for the application. Next, determine the required valve size based on the pipeline dimensions and flow rate needs.

Pressure and temperature ratings are crucial; the valve must withstand the maximum expected conditions without degrading. Consider the type of connection (flanged, wafer, or lug) that best fits your system’s requirements for ease of installation and maintenance. Actuation is another important factor; choose between manual, pneumatic, electric, or hydraulic actuation based on your automation needs and available utilities.

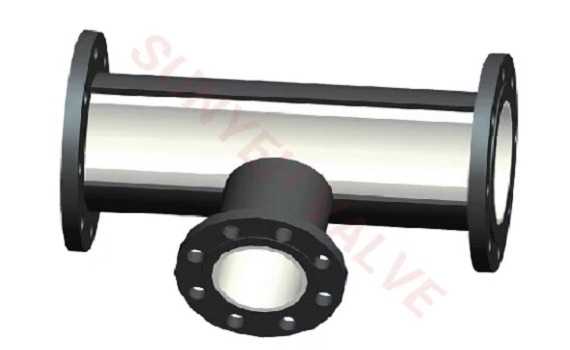

Finally, take into account the total cost of ownership, including initial costs, maintenance expenses, and potential downtime. Selecting a valve that balances these factors with the demanding conditions of your application will ensure long-term reliability and efficiency, reducing overall operational costs.

English

English