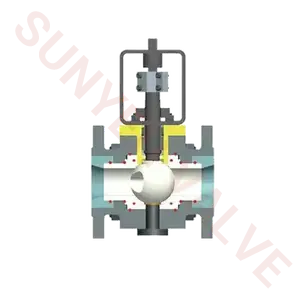

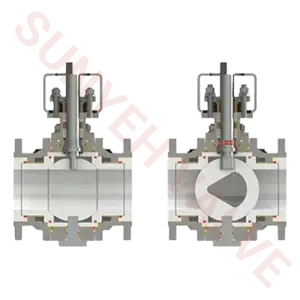

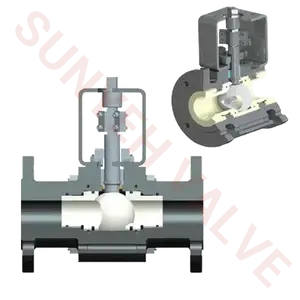

A V-port ball valve (V-port ball valve) is a special type of ball valve with a V-shaped internal passage. This design gives the V-port ball valve unique advantages in fluid control, especially in regulating flow and preventing cavitation. The following are some of the key features of V-port ball valves:

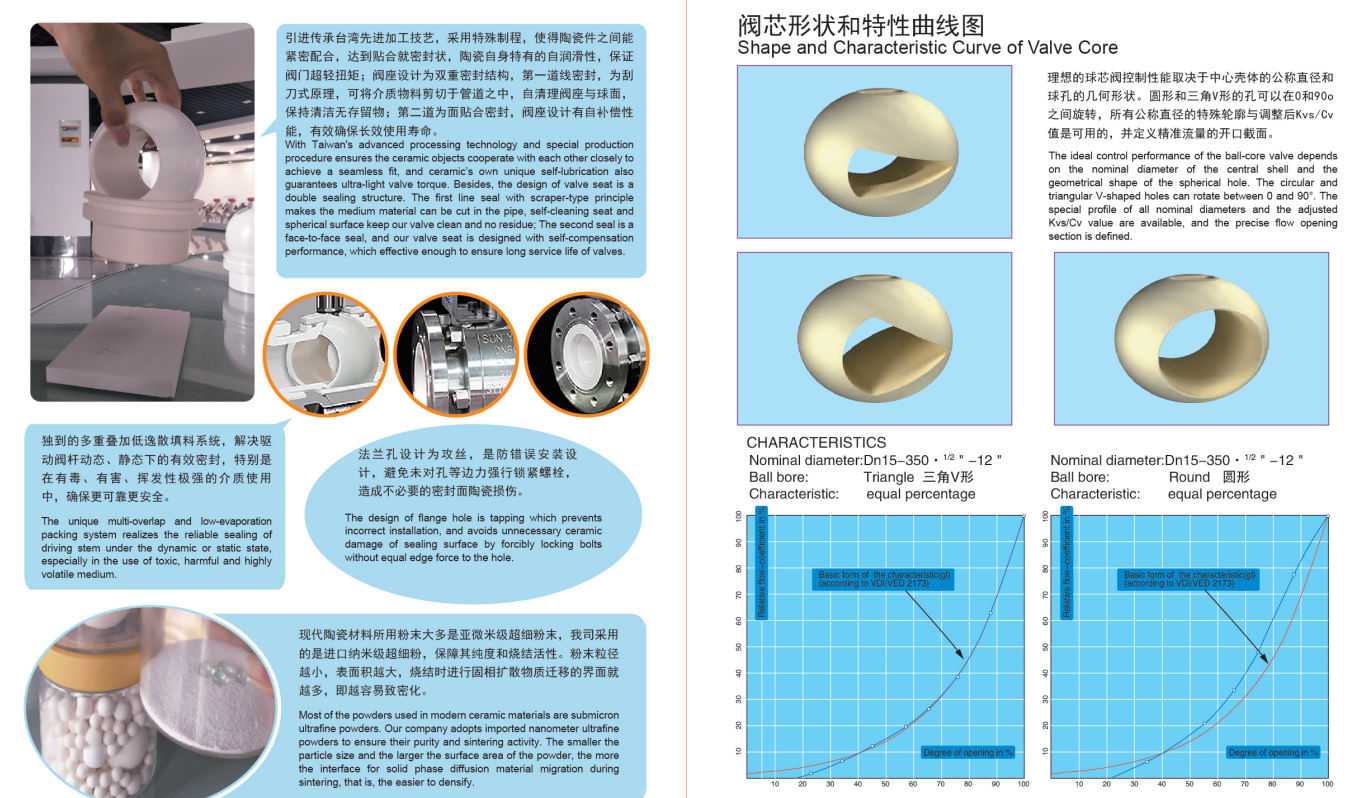

1. Flow regulation capability: The V-shaped design of the V-port ball valve allows the V-port valve to provide smooth flow regulation in the partially open state, which is useful for applications that require fine flow control.

2. Protection against cavitation: Due to the shape of the V-channel, V-ported ball valves effectively prevent cavitation from occurring when the v-port ball valve is closed, which is critical for protecting piping systems from cavitation-induced damage.

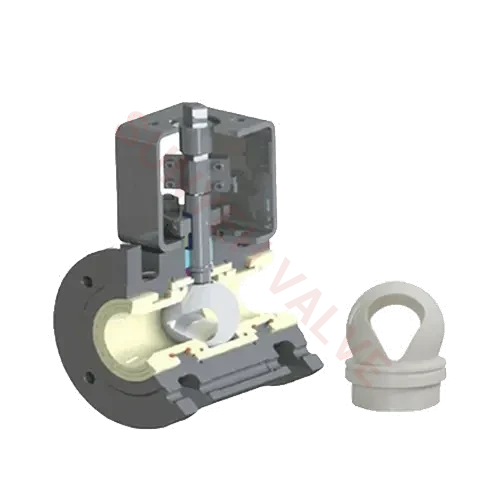

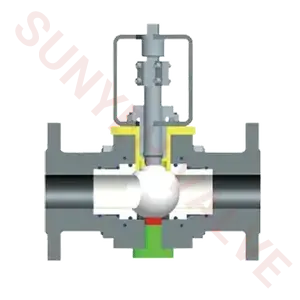

3. Sealing performance: V-port ball valves usually use metal-to-metal sealing or soft sealing materials to ensure good sealing performance and reduce leakage.

In terms of technological innovation, V-port ball valves may contain improvements in the following areas:

1. Application of new materials: With the development of material science, new wear-resistant, and corrosion-resistant materials are applied in the manufacture of V-port ball valves, which improves the durability and adaptability of the v port ball valves.

2. Precision processing technology: Advanced processing technology, such as CNC machine tools and laser cutting, can improve the manufacturing precision of V-port ball valves and ensure that the performance of the v port ball valve is more reliable.

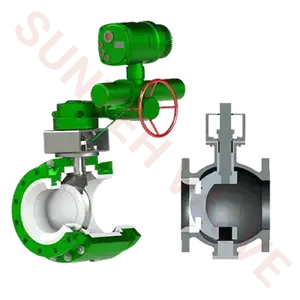

3. Intelligent control system: V-port ball valves with integrated intelligent sensors and control systems can realize automated control and improve operation efficiency and safety.

4. Environmentally friendly design: In response to environmental protection requirements, the design of V-port ball valves is increasingly focusing on energy saving and emission reduction, for example, by optimizing the flow path design to reduce fluid resistance and energy consumption.

Please note that the above is based on general V-port ball valve product technology, specific V-port ball valve products may vary, it is recommended to consult a professional supplier or manufacturer for the most accurate information when making a selection.

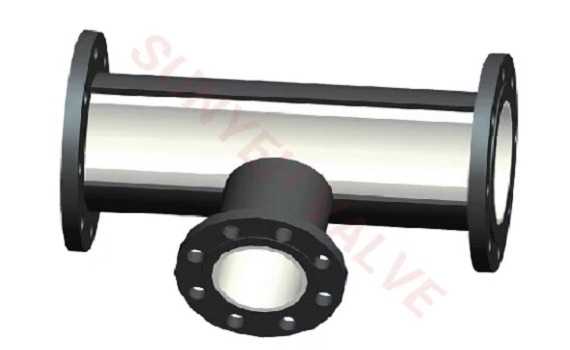

The V Port Ball Valve is a valve type commonly used for precise control of fluid flow. The v-port valve features a V-shaped opening in the ball, and this design allows the valve to provide good flow control when opening and closing, while also preventing backflow of the medium, and is suitable for controlling highly viscous, fibrous and particle-containing media. The V port ball valves are used in combination with pneumatic piston actuators or electric actuators and are widely used in the oil and gas, electric power, chemical, water treatment, light industry, and other industries.

1. Oil and gas industry: V Port Ball Valve can be used in oil fields for oil extraction and transmission pipelines, as well as treatment and distribution systems in gas treatment plants.

2. Chemical industry: In the process of chemical reaction, V Port Ball Valve can be used to control the flow of raw materials and products to ensure the smooth progress of the reaction.

3. Water Treatment and Wastewater Treatment: In water treatment facilities, V Port Ball Valves can be used to regulate the flow of water, control the quality of water, as well as control the flow of sludge during wastewater treatment.

4. Food and beverage industry: In food processing and beverage production, V Port Ball Valves can be used to control the flow of liquids and ensure product quality.

5. Pharmaceutical industry: In the pharmaceutical production process, the V Port Ball Valve can be used to control the mixing and dilution of drugs to ensure the accurate proportion of drugs.

6. Energy industry: In nuclear power plants and thermal power plants, V Port Ball Valves can be used to control the flow of fuel and steam to ensure the effective use of energy.

7. Other industrial applications: V Port Ball Valve can also be used in the fuel system of ships, automobiles, airplanes, and other means of transportation, as well as in building water supply and heating systems.

The above are some common application areas of V Port Ball Valve, the specific application scenarios may vary according to different industries and processes. When selecting and using the V Port Ball Valve, you need to consider the nature of the medium, temperature, pressure, flow rate, and other factors to ensure that the V Port valve works properly and is safe and reliable.

English

English