To make sure the highest precision, stability, and precision preservation of each machine, we as one of the leading ceramic ball valves manufacturers take in new casting material UHPC and build our casting workshop. For the current manufacture of the ceramic valve manufacturer, all machine bases and columns are cast by UHPC strictly according to German casting standards.

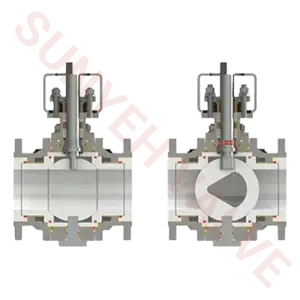

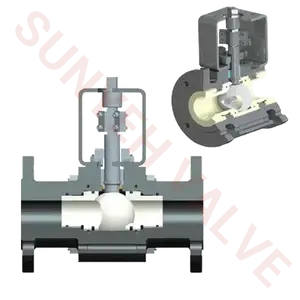

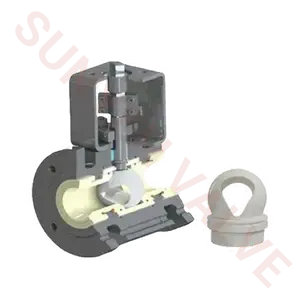

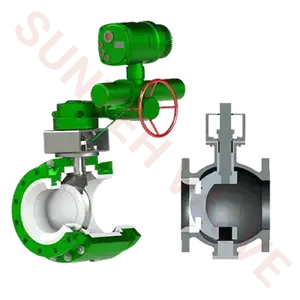

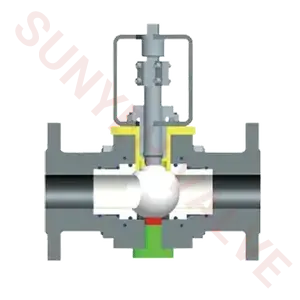

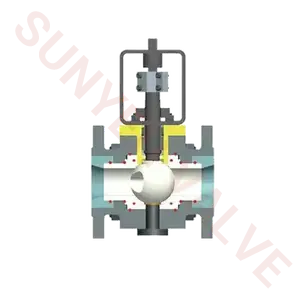

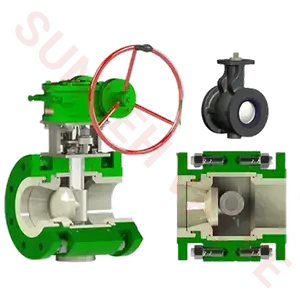

Ceramic lined ball valves, such as zirconia ceramic lined ball valves, alumina ceramic lined ball valves and ceramic lined valves for on off, find widespread use in a variety of industrial applications where the control of abrasive or corrosive fluids is critical. The unique properties of ceramic materials make them well-suited for challenging environments. Some common applications of ceramic lined ball valves include:

Ceramic Lined Ball Valve for Mining Industry:

In mining operations, ceramic lined ball valves are employed to control the flow of abrasive slurries containing minerals. The wear-resistant properties of ceramics, such as alumina in alumina ceramic lined ball valve or silicon carbide, make them ideal for mitigating the effects of abrasive particles, ensuring efficient and reliable operation.

Ceramic Lined Ball Valve for Chemical Processing:

Ceramic lined ball valves are utilized in chemical processing plants where corrosive chemicals are handled. The corrosion-resistant nature of ceramics helps prevent degradation over time, ensuring the integrity of the ceramic lined ball valves in the presence of aggressive chemical compounds.

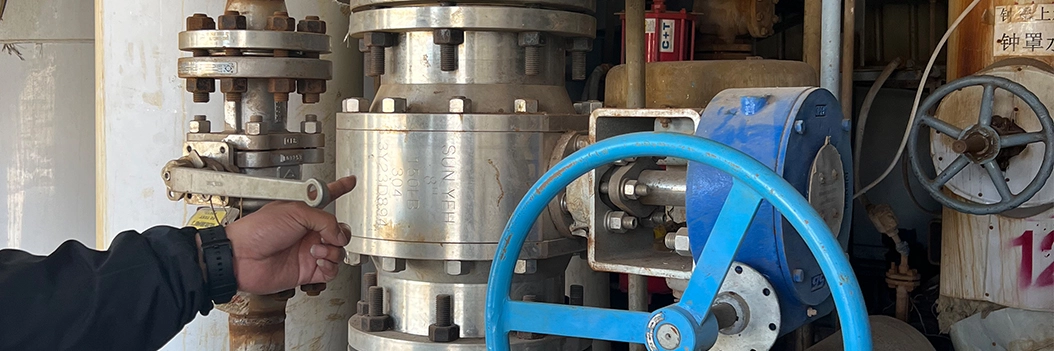

Ceramic Lined Ball Valves for Oil and Gas:

Within the oil and gas industry, ceramic lined ball valves are employed in pipelines and processing facilities. They provide effective control of fluids containing abrasive elements or corrosive substances encountered during the extraction, transportation, and refining of oil and gas.

Ceramic Lined Ball Valves for the Pulp and Paper Industry:

Ceramic lined ball valves play a crucial role in the pulp and paper industry, particularly in applications involving the transportation of abrasive slurries during the papermaking process. Their wear resistance ensures longevity and reliable performance in these demanding conditions.

Ceramic Lined Ball Valves for Power Generation:

Power plants, both fossil fuel and nuclear, utilize ceramic lined ball valves in various applications. These ceramic lined ball valves are suitable for controlling the flow of abrasive coal slurries, chemical additives, and other corrosive substances encountered in power generation processes.

Ceramic Lined Ball Valves for Water and Wastewater Treatment:

Ceramic lined ball valves are used in water and wastewater treatment plants where the control of abrasive or corrosive media is necessary. They contribute to efficient and reliable fluid handling in processes such as sludge handling and chemical dosing.

Ceramic Lined Ball Valves for Metal Refining:

Industries involved in metal refining, such as aluminum and copper smelting, utilize ceramic lined ball valves for their resistance to corrosive molten metals and abrasive particles present in the refining processes.

English

English