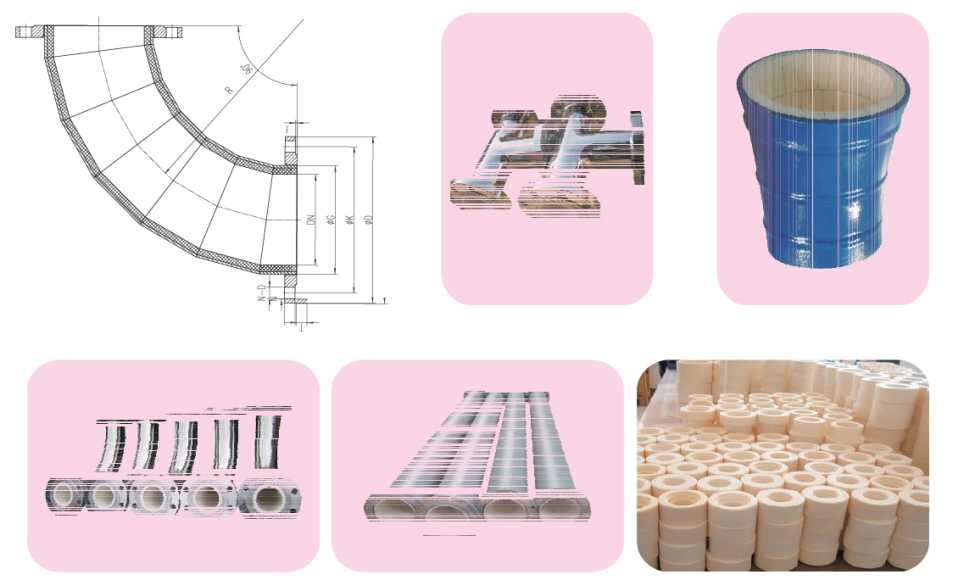

When choosing abrasion resistant ceramic lined pipes, you should consider the following key factors:

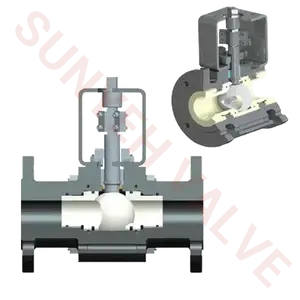

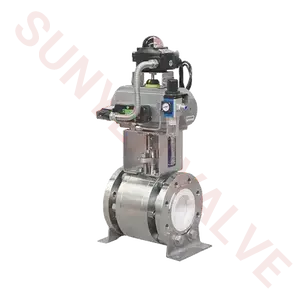

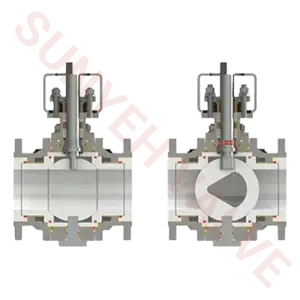

1. abrasion resistant ceramic lined pipe performance: the main function of abrasion resistant ceramic lined pipes is to resist wear and tear, so abrasion resistant ceramic lined pipes' abrasion-resistant performance should be prioritized when choosing. The hardness and wear resistance of the ceramic material are the key factors determining abrasion resistant ceramic lined pipes' performance.

2. Chemical stability: the abrasion resistant ceramic lined pipe may come into contact with corrosive media in the course of use, so it is necessary to choose materials with good chemical stability to avoid erosion of the abrasion resistant ceramic lined pipe leading to a shortened life.

3. Temperature adaptability: temperature changes in different working conditions may have an impact on the pipeline material, the choice of a good temperature adaptability of the material can ensure that the pipeline is in the high-temperature or low-temperature environment of normal operation.

4. Cost considerations: different materials abrasion resistant ceramic lined pipe cost differences, need to be based on the actual budget for comprehensive consideration.

5. Use environment: According to the specific working environment where the abrasion resistant ceramic lined pipe is located, such as the type of transported materials, particle size, the use of temperature and the flow rate of the material, etc., to choose the appropriate abrasion resistant ceramic lined pipe specifications and models.

6. Installation and maintenance: Considering the installation convenience and maintenance cost of the pipeline, choose the pipeline design that is easy to install and maintain.

7. Manufacturer's reputation: Choose well-known brands and manufacturers with good reputations to ensure the quality of piping and after-sales service.

8. Product standards: Ensure that the selected piping complies with relevant industry standards and codes to ensure abrasion resistant ceramic lined pipes' performance and safety.

By combining these factors, you can choose the abrasion resistant ceramic lined pipe that best suits your specific application needs.

English

English