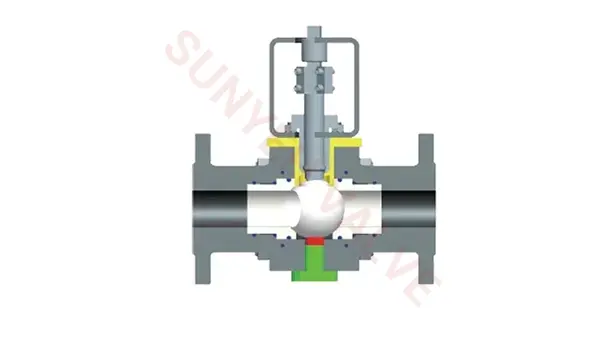

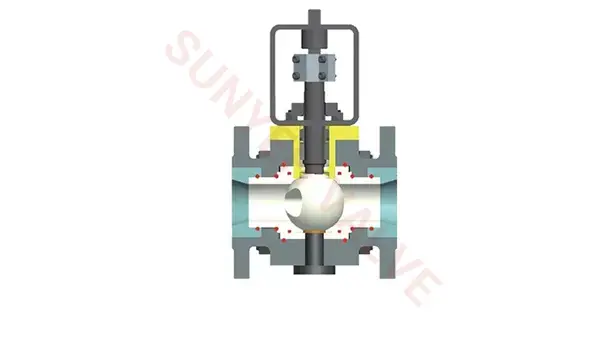

In order to meet the stringent requirements of modem industry, Sun Yeh Ceramic Ball Valves are made of various ceramic materials with unique processing characteristics, Alumina Ceramics are currently the most commonly used ceramic materials, and there are different purities of them on the market, from 76 porous refractories to 99.9 inert grade. Although low purity alumina is a relatively low-cost choice, its hardness and corrosion resistance are greatly reduced when comparedwith other ceramics with higher alumina content, Zirconia, silicon carbide and silicon nitride have their own unique characteristics and all can be used in Sun Yeh Ceramic Ball Valves series.

99.5 Alumina is the standard ceramic material for al Sun Yeh Ceramic Valves, such as the alumina ceramic lined ball valve. in addition to its strong corrosion resistanceand high hardness, 99.5 Alumina is not degraded by radioactivity, making it an ideal material for various corrosive applications, it remains stable at extremely high temperatures, and may even be used in places over 1000F degrees.

This high quality Alumina is one of the highest purity forms of Alumina avallable. it is finer, more uniform and has feweibonding materials than 99.5 Alumina. Therefore, its corrosion resistance and wear resistance have been greatly improvedmaking this kind of ceramics an ideal choice in the most harsh working conditions.

At high temperature, Silicon Nitride is superior to other ceramics, with remarkable heat shock resistance and high strengthOriginaly, it developed as an interal component for intemal combustion engines, turbines and diesel plugs, and now it canbe an optional ceramic material for Sun Yeh Valves. Silicon Nitride is so stable at high temperatures that it can be appliedwith molten metals.

The hardness of Silicon Carbide is harder than standard Alumina, and only next to that of Diamond and Boron Carbide. Atthe conditions of extreme temperatures, it exhibits high thermal conductivity, high heat shock resistance and strengthdurability. Among all fine ceramics,Silicon Carbide has the highest corrosion resistance and is one of the few hydrofluoricacid-resistant materials, which make it becomes the ultimate material of Sun Yeh Ceramic Valves.

At room temperature, Zirconia has the highest strength and toughness of al Engineering Ceramics, However, its corrosiorresistant is on general level and more susceptilble to impact and friction and wear, so it is mainly used in high torque, higherosion and high pressure applications.

English

English