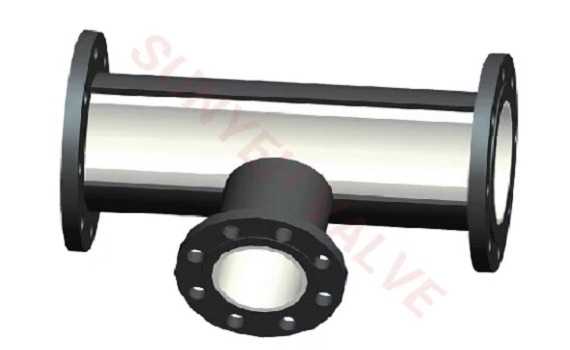

Sun Yeh ceramic-lined control valves, with their unique high-performance ceramic lining and exquisite manufacturing process, have deeply penetrated various manufacturing industries, becoming crucial equipment for ensuring production safety and enhancing efficiency. Below, we will detail the applications of these valves in various industries.

Application in the Power Industry:

In the power industry, coal is an important energy resource. Sun Yeh ceramic-lined control valves are primarily used here for pulverized coal transport, slag removal, and ash handling. Coal contains a large number of solid particles and corrosive substances, and traditional metal valves often wear out quickly and lose sealing performance after prolonged exposure to abrasive materials like coal dust. However, the high-performance ceramic lining of Sun Yeh ceramic-lined control valves not only provides strong wear resistance but also maintains stability at high temperatures, thus ensuring the safe and stable operation of conditions such as coal transport.

Application in the Metallurgical Industry:

The metallurgical industry, another sector with high demand for valves, generates a large amount of slag water and waste acid during the ore smelting process. These substances are highly corrosive and place great demands on the materials and structures of valves. Here, Sun Yeh ceramic-lined control valves are primarily used for coal injection, slag discharge, material unloading, and handling slag water. These conditions also involve large amounts of solid particles and corrosive substances, requiring high performance and material standards from valves. However, Sun Yeh ceramic-lined control valves stand out due to their excellent wear resistance and corrosion resistance, accurately controlling fluid flow in complex processes such as coal injection, slag removal, oxygen enrichment regulation, and nitrogen pressurization, ensuring smooth production.

Application in the Chemical Industry:

In the chemical industry, especially in processes involving strong acids and alkalis, the advantages of Sun Yeh ceramic-lined control valves are even more evident. Their smooth inner walls, which do not easily adhere to impurities, maintain good sealing performance in harsh conditions, preventing leaks and contamination. For example, in soda ash production facilities, these valves precisely control the flow of media like lime milk in critical equipment such as carbonation towers, ensuring the stability of chemical reactions. They also handle high concentrations of corrosive substances in conditions like salt mud and cold ammonia brine pump outlets, protecting the equipment from damage.

In titanium dioxide production enterprises, Sun Yeh ceramic-lined control valves are integral throughout the entire production process. From raw material pretreatment to final product processing, they provide precise control in every stage. Whether it's handling titanium dioxide slurry, bag filter air, or complex processes like furnace feeding and acid digestion, their excellent performance ensures continuous and stable production.

In coal chemical enterprises, Sun Yeh ceramic-lined control valves play a vital role. In the transport of substances like water-coal slurry and oil-coal slurry, they face challenges such as high viscosity and wear. In conditions involving synthesis gas and catalysts, they ensure the purity of fluids and accuracy of reactions.

In the silicon production industry, they ensure smooth material transport in the pneumatic silicon powder feeding process and prevent blockages. In the reactor feeding and discharging stages, the valves' high-temperature corrosion-resistant properties secure production safety and efficiency. For granular silicon processes, they precisely control various parameters to ensure product quality. In highly corrosive conditions involving hydrogen chloride and chlorosilanes, their lining material resists degradation, extending service life. Also, in filter slag outlets and exhaust gas pressure control stages, they exhibit outstanding performance.

Application in the Environmental Protection Industry:

With rising environmental awareness, the demand for valves in the environmental protection industry is growing. Here, Sun Yeh ceramic-lined control valves are mainly used in wastewater treatment and waste gas purification equipment. These conditions demand high sealing and corrosion resistance from valves, as wastewater contains a large amount of organic matter and bacteria that can erode and damage valves. However, Sun Yeh ceramic-lined control valves, with their superior performance and stable quality, ensure the normal operation of equipment, making a positive contribution to environmental protection.

Applications in Other Industries:

Besides the industries mentioned, Sun Yeh ceramic-lined control valves are also widely used in other sectors. For example, in the food and beverage industry, these valves are mainly used for controlling the production and processing of various liquid and powdered foods; in the textile and paper industries, they are primarily used for controlling the production and processing of various fibers and paper.

Sun Yeh ceramic-lined control valves, with their excellent performance, stable quality, wide application areas, and customized services, have gained market recognition and customer trust, becoming the preferred brand for many enterprises. These valves not only solve the stability and durability problems of traditional metal valves in harsh conditions but also precisely control fluid flow, enhancing the efficiency and reliability of entire systems, reducing operating costs, and providing strong support for ensuring production safety and environmental protection.

Industry

| Number of Collaborative Purchasers |

Applicable Conditions |

| Metallurgical Enterprises | 11 | Used for coal injection, slag discharge, unloading, slag water, carbon material transport, ash transport, waste acid tank, pneumatic lime fluorite transport, oxygen enrichment adjustment and decompression, nitrogen pressurization, pickling, medium pressure steam, gas, anhydrous ammonia, etc. |

| Soda Ash Production Enterprises | 10 | Used for carbonation tower lime milk, salt mud, cold ammonia brine pump outlet, hot ammonia brine pump outlet, hot mother liquor, ammonia water tank, etc. |

| Titanium Dioxide Production Enterprises | 14 | Used for titanium dioxide slurry, bag filter air, unloading, raw material unloading, chlorinator feeding, high titanium slag, gas-powder feeding, acid digestion, slurry mixing, sedimentation, crystallization, lime milk, filter press feeding, post-treatment, etc. |

| Coal Chemical Enterprises | 11 | Used for water-coal slurry, oil-coal slurry, scrubber towers, fly ash, fine coal, blackwater, slag water recycling pumps, low-pressure ash water, synthetic gas, catalysts, vacuum flash tank level adjustment, lock hopper first relief valve, etc. |

| Silicon Production Enterprises | 17 | Used for pneumatic silicon powder feeding, reactor loading and unloading, granular silicon process control, hydrogen chloride process, chlorosilanes, filter slag outlet, feeding into high-temperature high-pressure bins, exhaust gas pressure control, etc. |

| Power Plants | 9 | Used for pulverized coal transport, slag discharge, ash removal, unloading, water slag, etc. |

| ... | ... | ... |

English

English